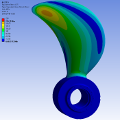

Turbine Blade Design

Turbine Blade Design

A gas turbine is a type of internal combustion engine that can be used to produce shaft work output, e.g. for driving an electric generator. In one of our recent projects with SIEMENS, we developed an easy-to-use and highly efficient workflow for the optimization of blade designs for stationary gas turbines, including endwall contouring.

Drone Blade Design

Drone Blade Design

The French company Parrot SA uses CAESES® as a customized design framework for drone propellers. Being one of the leading companies in the drone market, the engineers’ motivation for introducing CAESES® came from the goals of speeding up their design process and delivering optimal products.

Diesel Piston Bowl Optimization

Diesel Piston Bowl Optimization

Today‘s car manufacturers inevitably have to focus on the reduction of fuel consumption while maintaining high performance standards. In this respect, turbocharged direct injection diesel engines represent an appealing solution. The challenge in developing these engines is – in addition to above-mentioned reduction of fuel consumption and high performance standards – the reduction of raw emissions. This is a case study from VW.

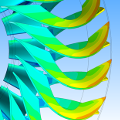

Turbine Blade Optimization including Scallops

Turbine Blade Optimization including Scallops

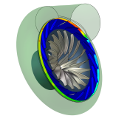

For the research project GAMMA, we developed a robust and variable geometry for a turbocharger turbine wheel, together with our customer MTU and the University Darmstadt (GLR). Besides the variable blade geometry, so-called scallops are also taken into account. The flow and the structural domain are derived from the parametric model for a comprehensive and automated optimization of the wheel.

Voith Linear Jet

Voith Linear Jet

The Voith Linear Jet (VLJ) combines the best properties of propellers with the best properties of waterjets. For this product, the design challenge is to maintain high efficiency across wide operating range while delaying the onset of cavitation. VLJ is an ideal propulsor for ships with mixed operating profile between low and high speeds like yachts, workboats, and patrol vessels.

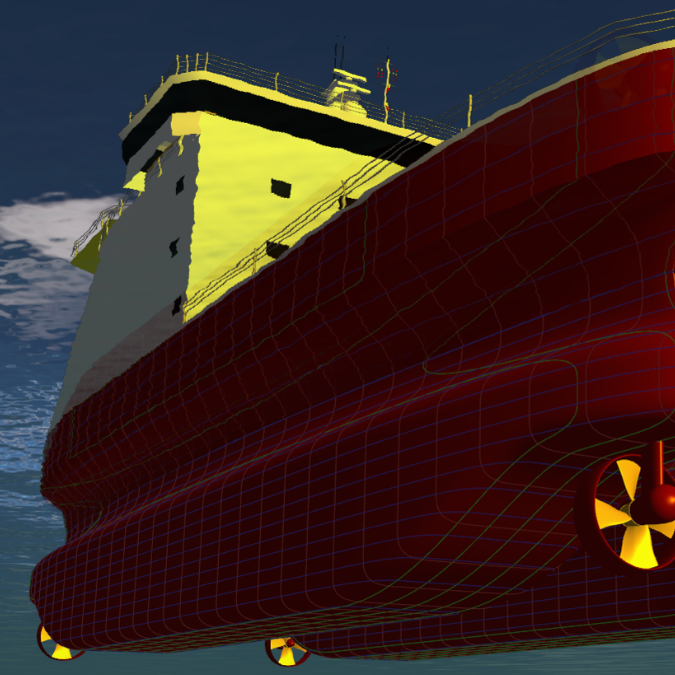

Bulk Carrier Optimization

Bulk Carrier Optimization

DNV GL assisted with bulk carrier optimization services for hull and machinery for a new type design Ultramax-size vessel called Diamond 2. For the hydrodynamic hull design the well-known ECO-Lines services of DNV GL were used, which also incorporate CAESES as the geometry modeler.

Torque Converter

Torque Converter

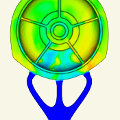

Automotive torque converters are a type of fluid coupling used in vehicles with automatic transmissions to transfer rotating power from the engine to the drive shaft. Designers of torque converters strive to maximize efficiency and torque ratio at high speeds by minimizing cavitation in the device and ensuring good flow behavior of the transmission fluid.

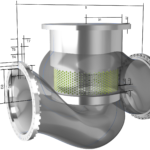

Control Valve Optimization

Control Valve Optimization

Control valves are used in a wide range of industries, and they regulate the flow of various fluids. For a project at ARCA Valves, the flow through such a control valve needed to be optimized. The challenge was to design a flexible parameterized geometry model of the valve housing that additionally incorporated a set of constraints.

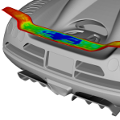

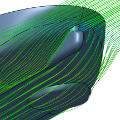

Rear Wing Optimization with Adjoint CFD

Rear Wing Optimization with Adjoint CFD

In this case study, the rear wing of a hyper sports car was optimized with respect to the drag and downforce. For the adjoint CFD computations, the flow simulation package iconCFD was utilized. The parametric model of the rear wing was set up in CAESES®, as well as the mapping of the adjoint solution to the geometry parameters.

Tidal Stream Turbine

Tidal Stream Turbine

When the French marine technology experts at Sirehna set out to design the turbine for OpenHydro, the Irish tidal technology specialist, for the world’s first large-scale tidal energy farm, they turned to CAESES® for it’s design and optimization. CAESES®’ Upfront CAD was used to design the turbine. This geometry model enabled automated generation of design variants ready to go for simulation.

Optimization of a Vertical Axis Wind Turbine

Optimization of a Vertical Axis Wind Turbine

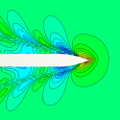

FRIENDSHIP SYSTEMS investigated the aerodynamic behaviour of a vertical-axis wind turbine (VAWT) in collaboration with the US-based company Pointwise. In a first phase of what should be a multi-phase effort, FRIENDSHIP SYSTEMS was able to demonstrate successfully how to automate mesh generation with Pointwise, integrate Pointwise into CAESES®, and use the two (along with other tools) to optimize in 2D the VAWT.

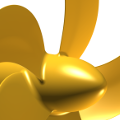

Workflow for Propeller Design

Workflow for Propeller Design

In 2014, Caterpillar Propulsion introduced CAESES® for the design of propeller blades. When we started on a project basis, the overall idea was to implement CAESES® as some sort of workbench that integrates and controls all the participating meshing and simulation software. At the same time, CAESES® should also deliver the 3D parametric blade design which allows the Caterpillar engineers to remodel their existing blade and profile definitions, but also gives high flexibility for trying out completely new designs.

Propeller Design with OpenFOAM

Propeller Design with OpenFOAM

FRIENDSHIP SYSTEMS prepared an example for linking CAESES® to OpenFOAM for a workshop that was held in October 2014. The following summary is also available as tutorial. The blade is generated by using the “Generic Blade” type of CAESES®. With this, one can define custom profile descriptions, as well as radial distributions for each profile parameter.

Optimization of a Mega Boxer

Optimization of a Mega Boxer

With a capacity of 14,000 TEUs, an overall length of 365.5 meters and a deadweight of 165,517 metric tons, the MSC Danit became the world’s largest container vessel when finished by Korean shipyard Daewoo Shipbuilding & Marine Engineering (DSME) in 2009. DSME used CAESES® for the optimization of proven parent ships.

Optimization of a Jack-Up Vessel

Optimization of a Jack-Up Vessel

DEKC Maritime has been responsible for the design and engineering of a retrofit of a self-propelled jack-up vessel. For this retrofit, the spudcans (the “feet” of the jacking legs) were increased in size to lower the pressure exerted on the sea bed. Also, to increase the cargo capacity, the design draft was increased and sponsons were added along the side of the vessel.

Optimization of a SWATH SOV Concept

Optimization of a SWATH SOV Concept

In this project, an innovative SWATH (Small Waterplane Area Twin Hull) hull form was investigated as an SOV (Service Operation Vessel), optimized and compared to operating monohull SOVs. The hull form was idealized by members of Rolls-Royce Marine Norway and inspired by semi-submersible platforms and SWATH vessels.

Container Vessel Hull Form Optimization

Container Vessel Hull Form Optimization

MARIC (MARINE DESIGN & RESEARCH INSTITUTE OF CHINA), is one of the leading companies in the Chinese maritime industry, and is a relatively new user of CAESES®. One of their first projects using CAESES® is for in-depth research for container vessel hull optimization.

Axial Compressor for Aeroengine

Axial Compressor for Aeroengine

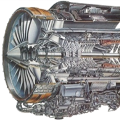

For the optimization of an axial compressor blade, in a collaboration with Rolls Royce Deutschland (RRD), two different optimization approaces were chosen and compared. The results of this study showed that both approaches led to very similar results, while the parametric 3D blade model in combination with a different optimization strategy helped to achieve these results within a very fast time frame.

Die Casting Optimization

Die Casting Optimization

Die casting is a metal casting process where molten metal is forced into a mold cavity. We have worked on several projects in this field together with our partner Flow Science, the makers of FLOW-3D. For this case study, the shape of a die casting component was optimized.

Optimization of a Large Turbocharger

Optimization of a Large Turbocharger

An automated and simultaneous optimization of a vaned diffusor and volute of a centrifugal compressor for a large turbocharger was studied in this project at TU Darmstadt (Institute of Gas Turbines and Aerospace Propulsion). The study was done in cooperation with NUMECA Germany and Kompressorenbau Bannewitz (KBB). For the automated generation of geometry, CAESES® came into play, while NUMECA products were used for the meshing and CFD part.

Axial Fan Optimization

Axial Fan Optimization

CFD Support and FRIENDSHIP SYSTEMS jointly worked on an efficient and automated design workflow to optimize the rotor blades of an axial fan. The motivation and starting point of this work was the fact that fan designers and fan manufacturers often have good baseline designs of axial fans that they want to further optimize and improve.