Design and Optimization of Valves

Ever-increasing technical requirements and competitive pressure, stringent manufacturing constraints, and a wide spectrum for shape variation, lead to a very high level of complexity in the design of state-of-the-art valves, with typical goals such as smoothening the flow path, reducing dead space, improving flushability, and minimizing pressure drop. Modern simulation tools allow the designers a good insight into the performance measures of interest, but can be challenging and time-consuming to employ on a wider scale, especially when performing parameter studies. A proven way to overcome these challenges is automated design exploration and optimization.

Optimization and automated design exploration augment the development process by leading to better and optimized designs, shortening development times and reducing design cycles, as well as increasing the knowledge about the product’s behavior, i.e., the influence of various parameters on its performance, early in the design process, when the freedom for making decisions is largest.

Apart from the aforementioned simulation tools, two crucial components are needed to achieve the desired process automation: a driver of the optimization process with appropriate systematic variation and optimization strategies, and a suitable CAD tool that can reliably produce the different geometry variants that should be analyzed.

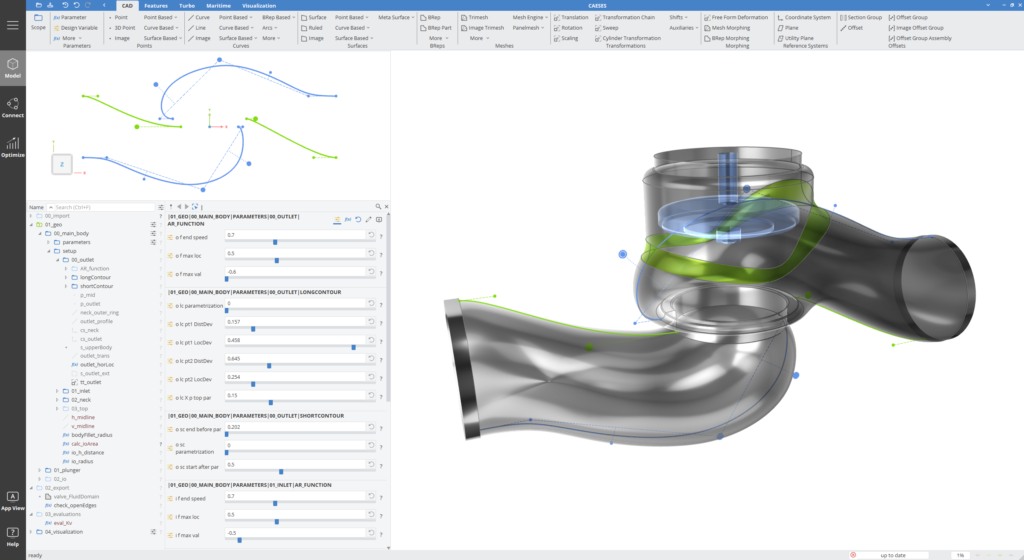

CAESES® is a comprehensive software solution for exploring and optimizing complex valve designs. CAESES® bridges the gap between traditional CAD and simulation. It provides intelligent geometry models for robust shape variation, and CFD automation to conduct design explorations and optimization. In particular, the focus of CAESES® is the simulation-ready and variable CAD.

Why Would I Need an Additional CAD System?

In our experience, the primary bottleneck in setting up and running an automated design exploration or optimization process is related to the handling of the geometry:

- Geometry variation with traditional CAD systems is often tedious or prone to failure, i.e., some or even many of the variants fail to regenerate when changing parameter values.

- Too many parameters make optimization inefficient.

- Simulation engineers depend on the CAD department to provide geometry (variants).

- It is difficult to consider, or even automatically fulfill, given constraints.

- The quality of the CAD model might not be suitable for simulation (e.g., w.r.t. watertightness, level of detail).

For the most part, CAESES® is a highly specialized CAD system that specifically tackles these problems. It is focused on parametric modeling and variation of complex geometries for design studies and optimization. It provides efficient parameterization methods that offer a high degree of flexibility while using less parameters, comprehensive capabilities for integrating constraints, and simulation-ready exports that require no manual processing.

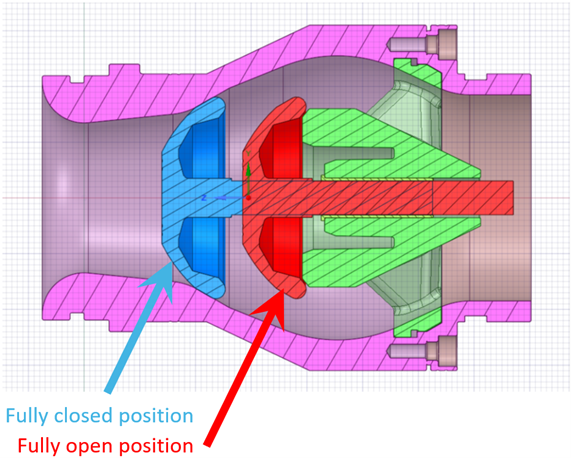

Valve Design Capabilities

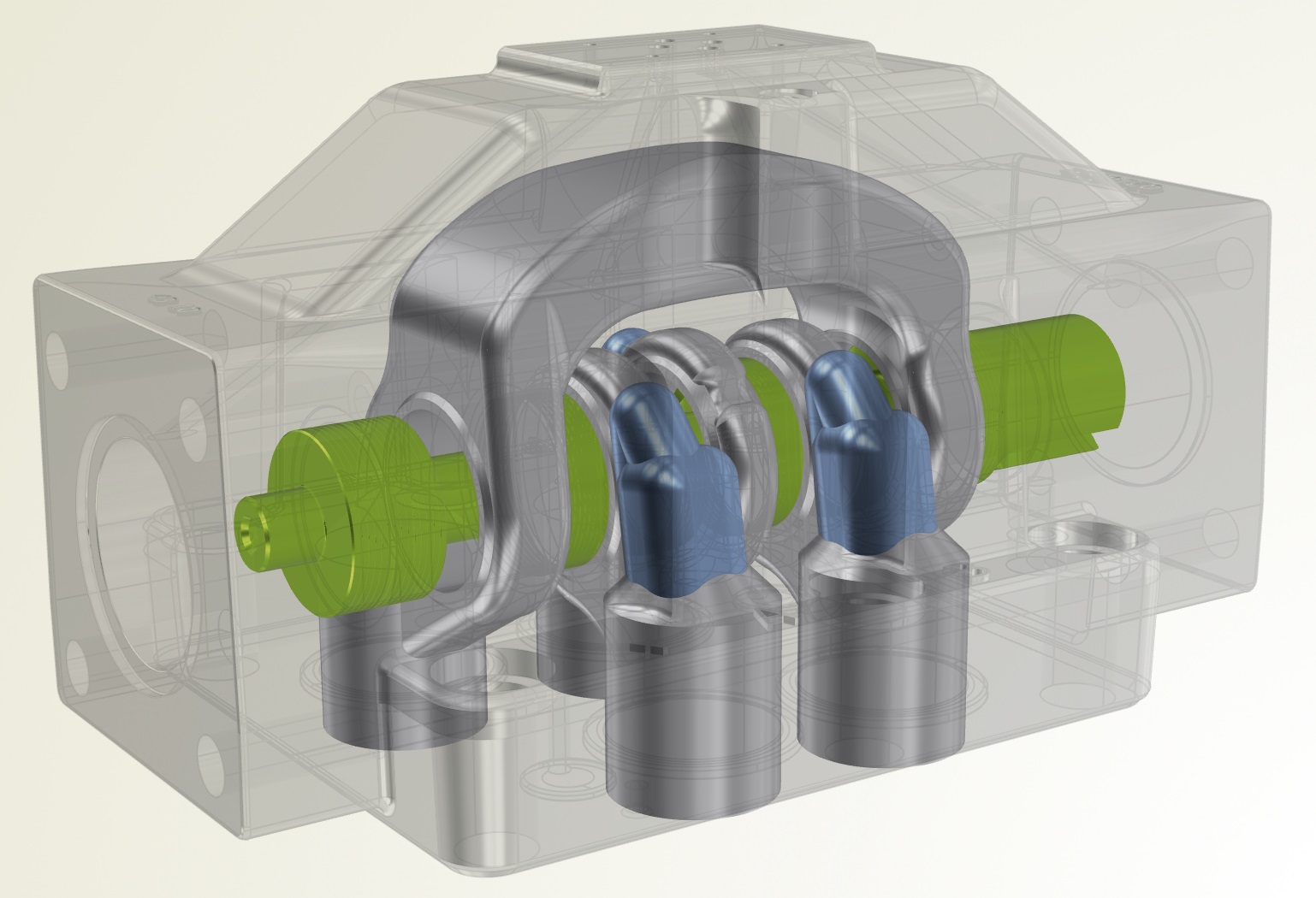

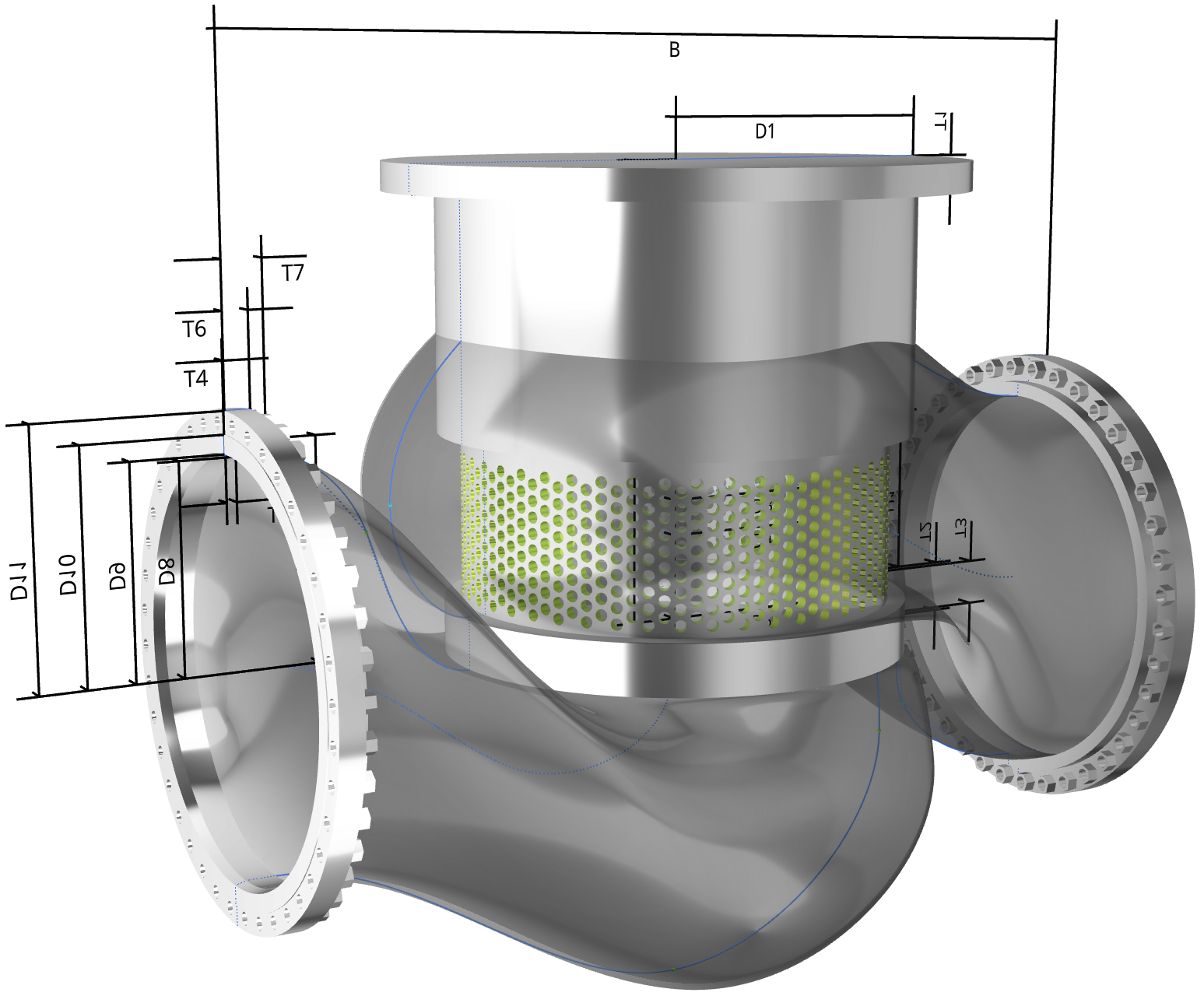

CAESES® comes with an extensive set of capabilities to support the design and optimization of valves:

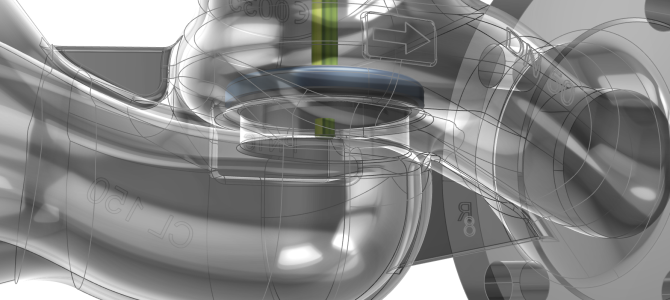

- Comprehensive parametric modeling of arbitrary geometries based on fully user-defined parameterizations, with a special focus on complex – often free-formed – geometries that are typically difficult to parameterize in traditional CAD systems.

- Alternatively, flexible and powerful morphing capabilities for quick but highly controlled modification of imported geometries (discrete or NURBS based).

- Robust variation with no failed variants.

- Full consideration of constraints, e.g., due to manufacturing and packaging reasons.

- Geometry exports in several different formats suitable for your CFD/meshing tools. Most of the formats support patch naming, so that downstream tools can correctly identify surface patches for the assignment of individual mesh settings or boundary conditions.

- Generic interface to easily connect CAESES® to external simulation and calculation tools (often CFD, but also other disciplines, such as structural analysis.).

- Fully-featured optimization environment with a wide selection of DoE and optimization strategies, as well as data management and post-processing capabilities.

- Full scriptability, to easily integrate CAESES® in third-party optimizers or custom workflows.

Valve Applications

CAESES® can cover the complete ranges of valves, including:

- Globe valves

- Gate valves

- Check valves

- Needle valves

- Spool valves

- Ball valves

- Butterfly valves

- Diaphragm valves

Who Uses CAESES?

Leading valve manufacturers, such as GEMÜ, ARCA, Duplomatic, and Danfoss, as well as research labs and academic institutions use CAESES® for the design and optimization of valves.

Case Studies and Blog Posts for Valve Applications

Try it Yourself

1. Download CAESES® and register for a trial license.

2. Create a geometry from scratch and set up an optimization workflow following the tutorials that you can find in CAESES®.

Questions ?

Please do not hesitate to get in touch with us if you have questions in the context of your specific application. We look forward to discussing it together with you!