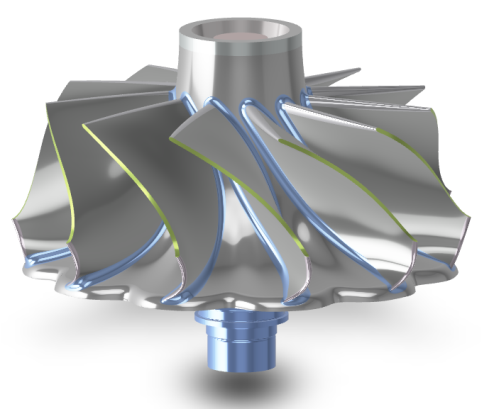

Turbine Blade Optimization including Scallops for a Turbocharger

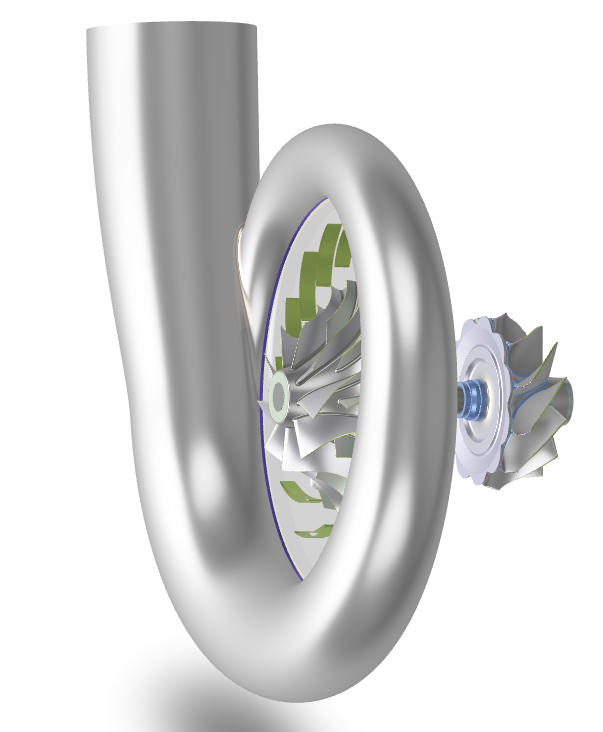

For the research project GAMMA, we developed a robust and variable geometry for a turbocharger turbine wheel, together with our customer MTU and the University Darmstadt (GLR). Aim of the project GAMMA (“Effiziente GAsmotoren für MaritiMe Anwendungen der nächsten Generation”) is the development and the preparation of new technologies and their interaction within the complete system based on LNG / natural gas as fuel for the next generation of efficient ship propulsion systems.

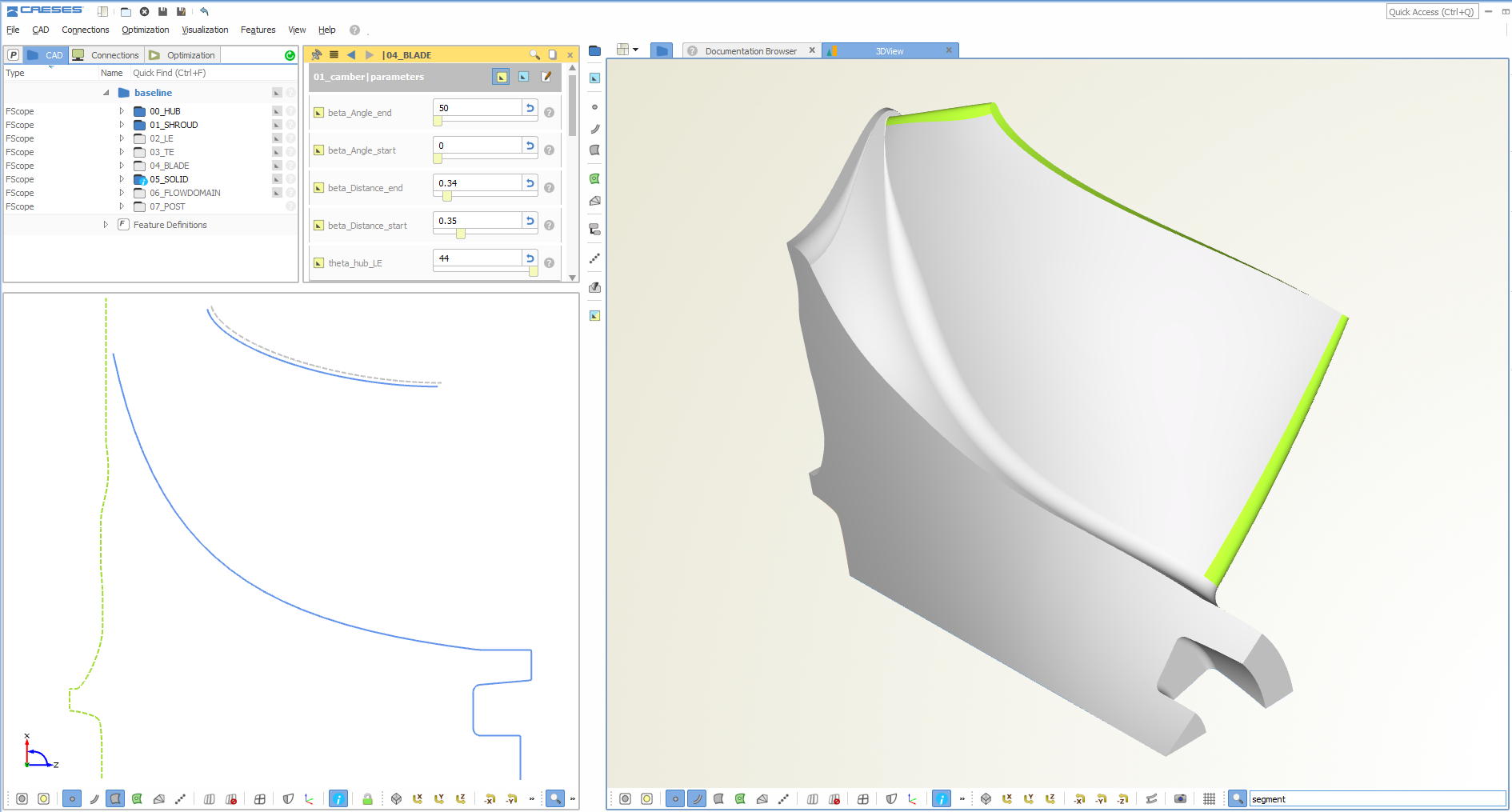

In the context of the turbine design, the idea was to create a geometry model with CAESES® for use within a shape optimization process that includes automated CFD simulations and stress analysis for each new design candidate. Besides the variable blade geometry, so-called scallops are taken into account in this geometry model, too.

Combining CFD and Stress Analysis Requirements

Often the CFD simulation engineers and the stress analysis experts are separated in different departments, using their own geometry representations of the turbine wheel. The goal of this work was to create a generalized geometry model for an automated optimization that covers the complex requirements from both engineering fields. By making the aerodynamics department able to automatically consider stress analysis in their optimization loop, the overall turbine design time can be substantially reduced.

Turbine Blade

The blade shape of this model is controlled by a set of parameters that can be changed manually and fully-automated through optimization strategies. All the shape changes should be 100% robust, and only feasible designs should be generated (e.g. feasible in terms of manufacturing constraints). Due to the substantial simulation efforts for a single design, the model changes need to be very efficient regarding the number of parameters and their effects.

Scalloped Turbine Wheel

Scallops are widely used among turbocharger manufactures. Basically, what you do is to reduce some mass of the turbine wheel at a large radius which leads to a beneficial decrease in inertia and centrifugal stresses. However, these shape changes typically introduce undesired aerodynamic performance losses. Hence, the challenge is to find a scallop-shape (and, at the same time, a corresponding blade design) that is the best compromise when investigating the flow and the stress characteristics.

Periodic Geometry

For the automated optimization process, the flow domain of the periodic geometry was also modeled and automatically transferred to the CFD tool for each new design candidate. For meshing and CFD, the software packages from NUMECA are used.

For strength analysis, only a single blade is considered. The maximum fillet radius at the hub is automatically calculated by the parametric model using internal geometry optimization techniques.

Customer Interview

There is an interview “Creating Lighter and More Efficient Radial Turbines” with Nicolas Lachenmaier, who is the leading aerodynamics & thermal turbine engineer at MTU. Read how the use of CAESES® models massively brought down the overall engineering time from several months to only a few weeks!

By using CAESES, we could massively bring down our turbine design cycle from several months to only a few weeks.

— Nicolas Lachenmaier, Engineer for Fluid Dynamics and Thermal Analysis, MTU Friedrichshafen

Downloads

A short summary of the CAESES® turbomachinery design capabilities can be found in this tech brief (PDF). There is also another tech brief (PDF) for the radial turbine design at MTU.

For more details including pictures and explanations, please take a look at the presentation “Parametric design of turbomachinery components for fully automated shape optimization with CFD and stress analysis“. It was presented at the CAESES® European Users’ Meeting 2017.

More Information

Please get in touch with us if you have any questions or if you are interested in turbine design and optimization. See also our turbomachinery section for related examples and more details. This turbine model is part of a complete parametric assembly that includes the volute, the compressor and the blade described in this case study. If you are interested in shape optimization of volutes and compressors, just drop us a line.