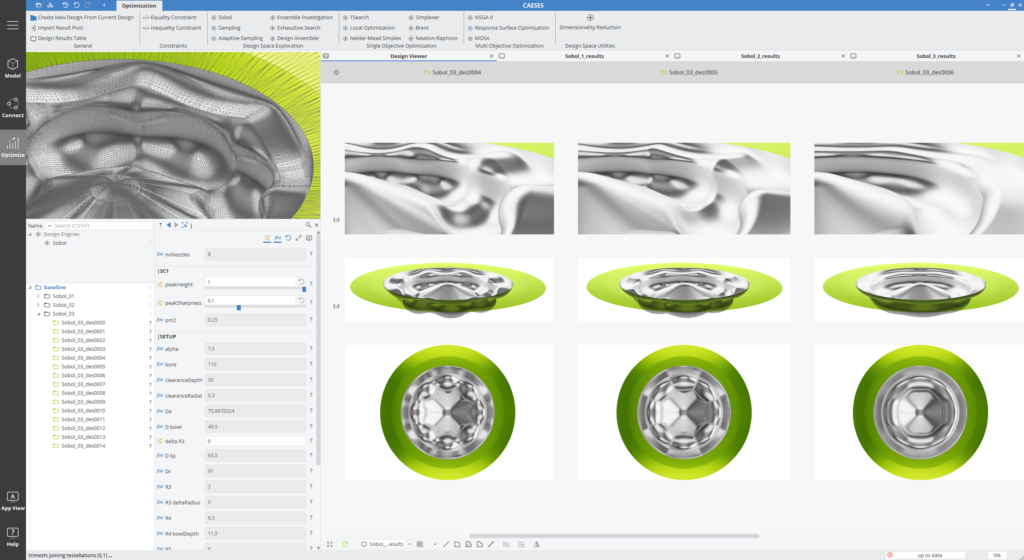

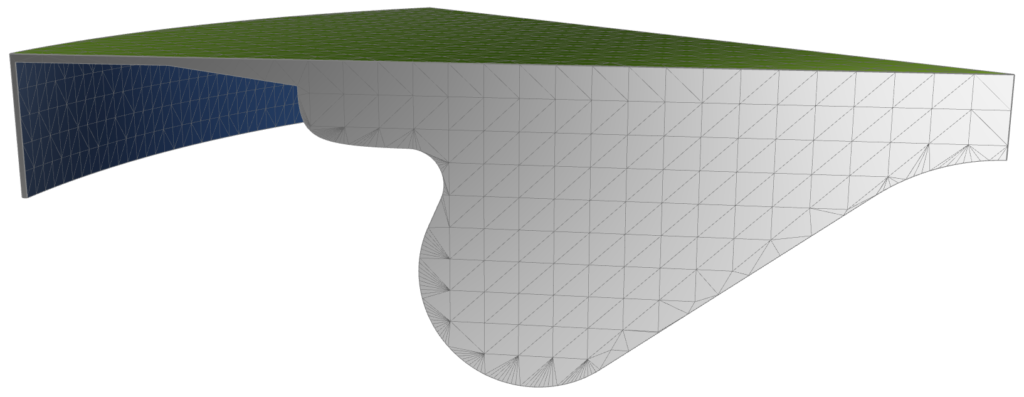

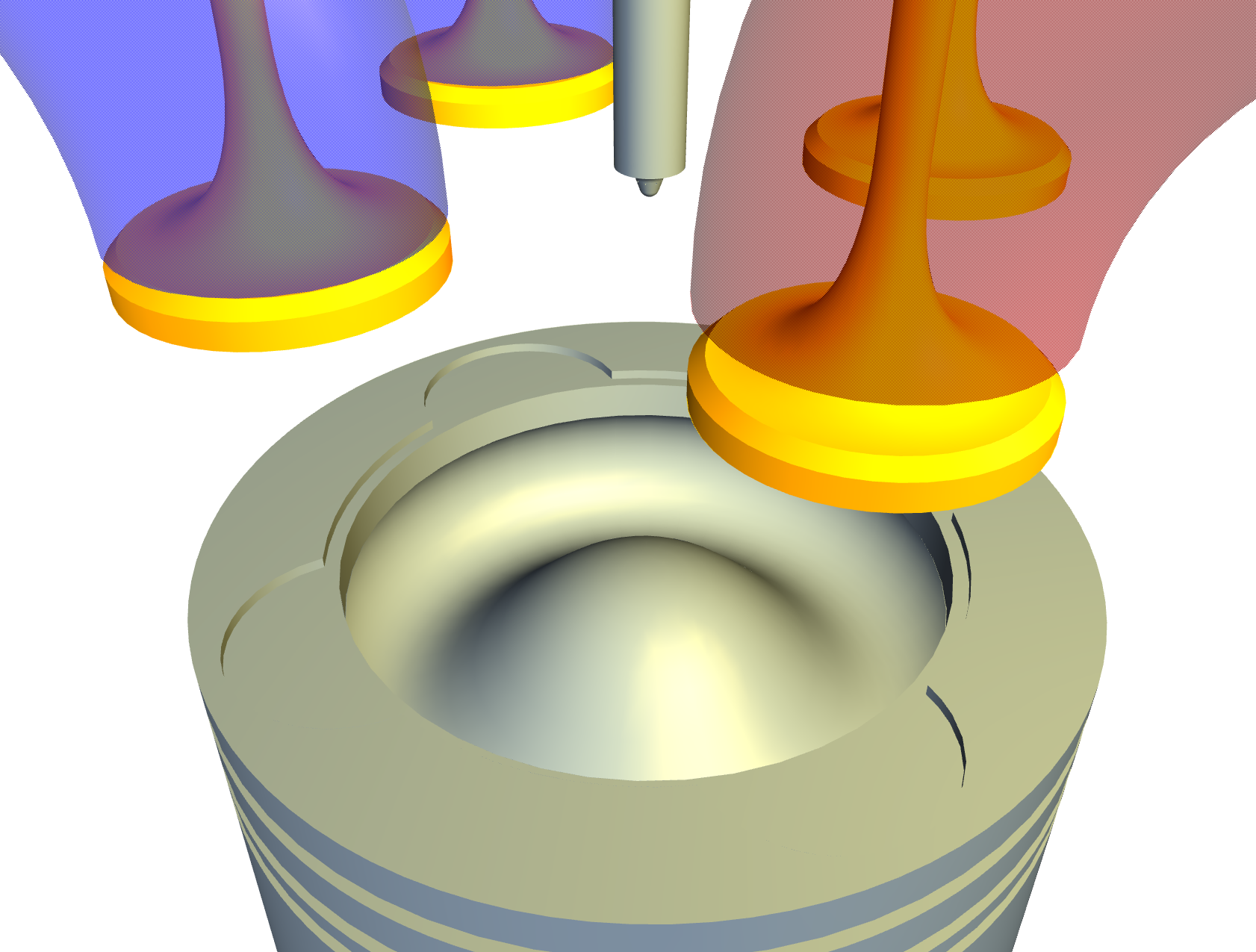

Piston Bowl Design

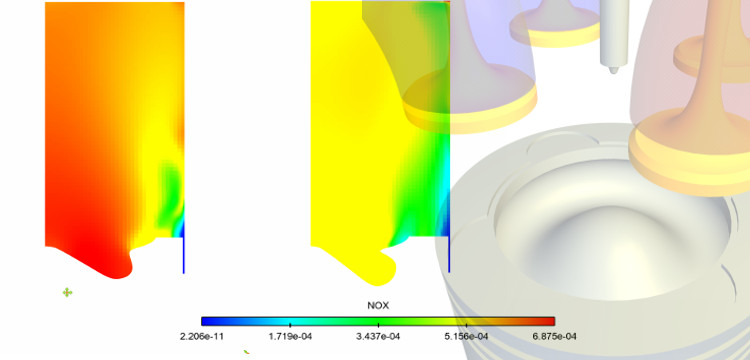

A piston bowl is a recess in the piston crown primarily used in (direct injection) Diesel engines, where it forms the combustion chamber. The design and shape of the piston bowl influences the movement of air and fuel during the compression stroke, thereby affecting the air/fuel mixture. A good mixture leads to a more efficient combustion, resulting in more power or better fuel economy. Additionally, using an effective piston bowl shape can reduce the in-cylinder emissions (like NOx and soot) and the cost for after-treatment.

CAESES’ Piston Bowl Design Capabilities

CAESES® is a dedicated CAD and automation environment for exploring and optimizing complex and performance-critical geometries (see also this overview on powertrain applications). In particular, it brings along several key capabilities for designing state-of-the-art piston bowls:

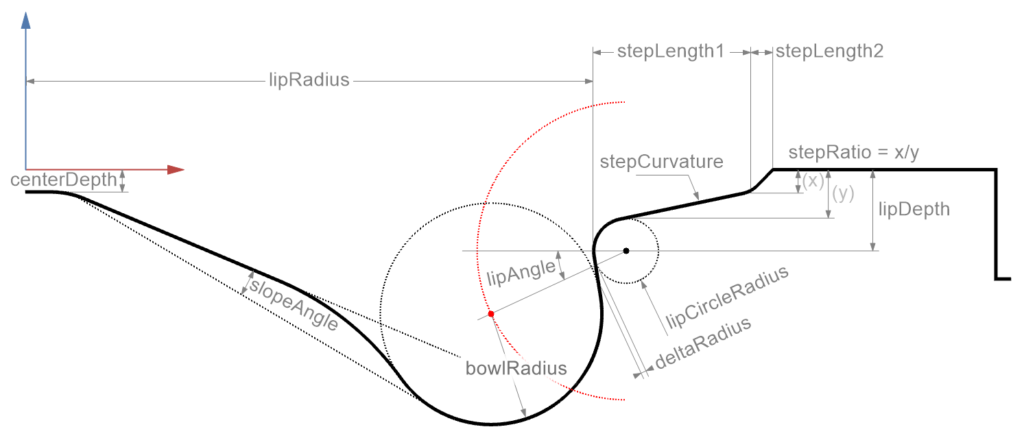

- Arbitrary, fully user-defined, profile parameterizations can be used. The design of your specific piston bowl is not limited to a set of provided templates. You want to use linear and circular segments, or rather splines? It doesn’t matter, they can be freely chosen and flexibly combined.

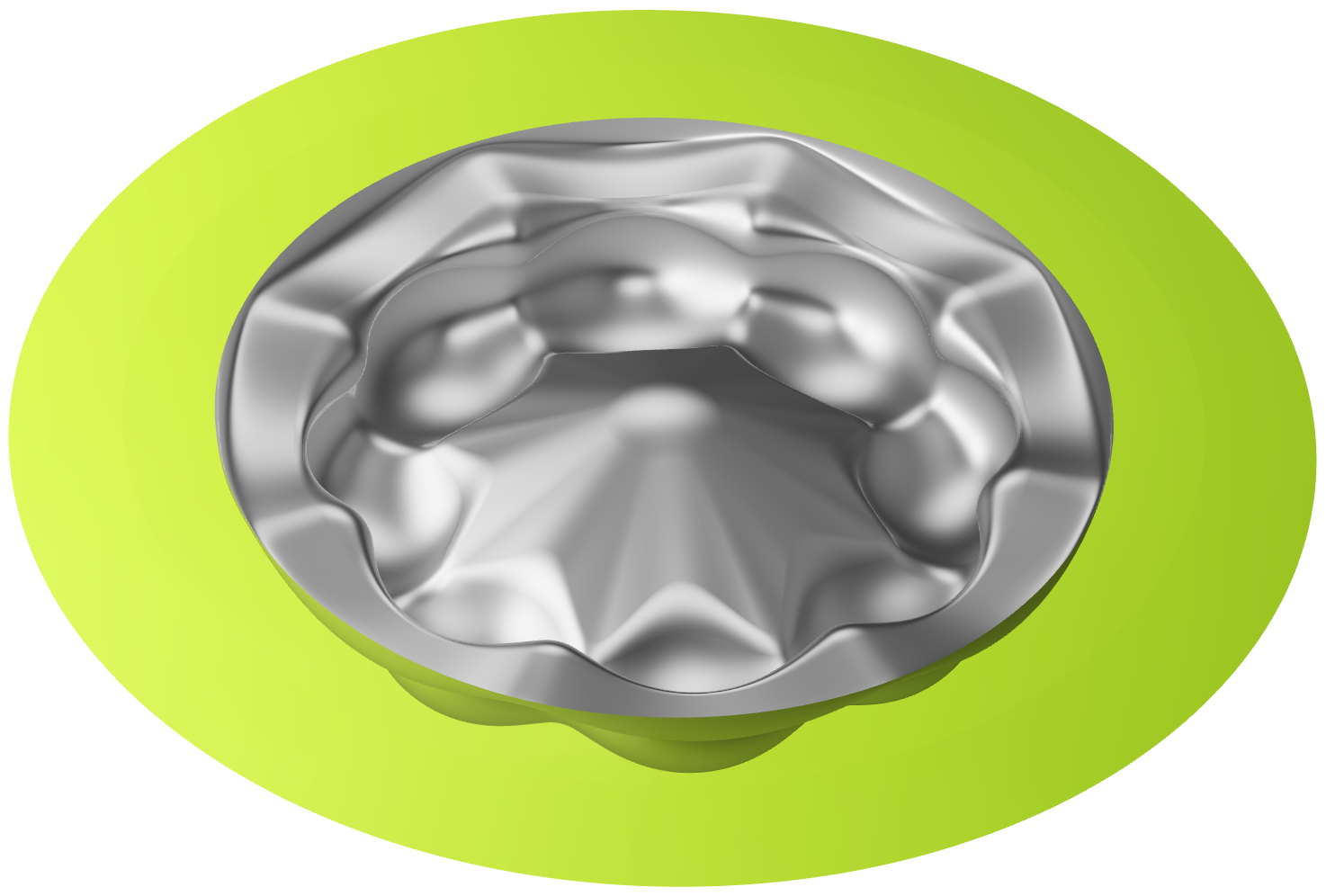

- The bowl profile can also be varied in circumferential direction, allowing for, e.g., “wavy” bowl shapes.

- Robust variation of the bowl geometry is possible with no failed variants. As for other geometries, one of the most important targets of our software is 100% robust geometry variation, obtained by smart parameterization and dependency-based models.

- The compression ratio can be automatically adjusted for each geometry variant. This is crucial for making sure that every generated variant has the same compression ratio and not wasting time on infeasible designs. This is realized with an internal optimization loop, where the variables used for the adjustment can be chosen freely. It is even possible to define an order of precedence, so that the automated adjustment procedure first tries to match the compression ratio with the first given variable. If that doesn’t suffice, the next variable is added, and so on.

- Other automated adjustments can be carried out as well, like spray targeting in relation to the changing bowl shape.

- The geometry can be exported in several different formats suitable for your CFD/meshing tools (including CONVERGE “surface.dat”). Most of the formats support patch naming, so that the downstream tool can correctly identify surface patches for the assignment of individual mesh settings or boundary conditions.

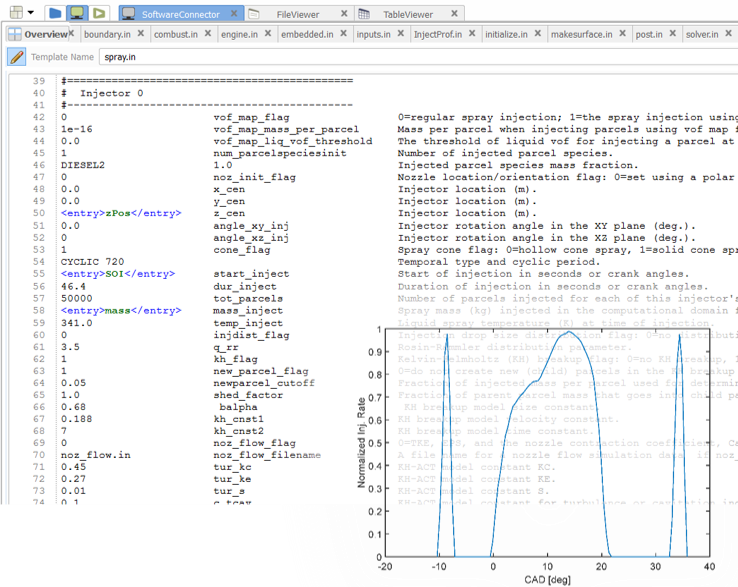

- A design study on the piston bowl geometry can be combined with an investigation of the injection strategy, or other process parameters (such as fuel composition, EGR amount, etc.). In our Software Connector interface, we can parameterize and modify any value that goes into the input files or scripts for the CFD solver.

Learn More

Piston Bowl Design with CAESES – Do it yourself!

1. Test the online demo model below.

2. Download CAESES®, register for a trial license, and open the piston bowl sample file downloaded in the previous step.

3. Watch the corresponding video for explanations.

4. Create a geometry from scratch with the piston bowl modeling tutorial in CAESES®.

PISTON BOWL

This is a demo of a parametric piston bowl with automated adjustment of the compression ratio. The final geometry can be downloaded as colored STL, in CONVERGE CFD format, or as a CAESES project file.

Case Studies and Blog Posts for Piston Bowl Design

Questions?

Please do not hesitate to get in touch with us if you have questions in the context of piston bowl design or your specific application. We look forward to discussing it together with you!