In this short blog post, we want to focus on the design of piston bowls for diesel engines – from a geometrical point of view … as we usually do as Upfront CAD enthusiasts. In our recent powertrain-related projects (here is an example), we have been repeatedly faced with the same design constraint:

Creation of an optimal bowl shape while the compression volume is a user input, and therefore fixed.

OK, this is not that complicated, but the idea is to keep this volume automatically fixed during design studies for each new design. This makes sure that only feasible designs are generated, and allows engineers to explore hundreds of suitable designs quickly. Piston bowls are not the only application where the engineer needs to consider constraints like this, of course. So the following example is a more general task where geometrical quantities such as a (section) area, an area ratio, a volume, a centroid, center of buoyancy etc. are fixed right from the beginning of the project.

An Example

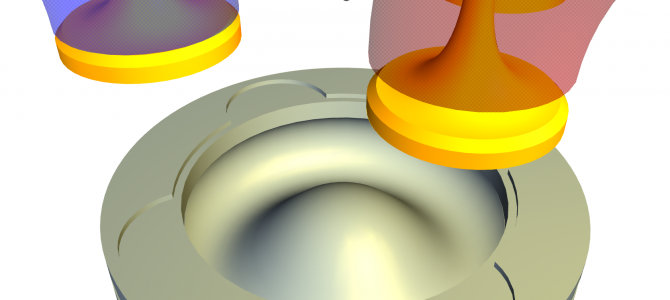

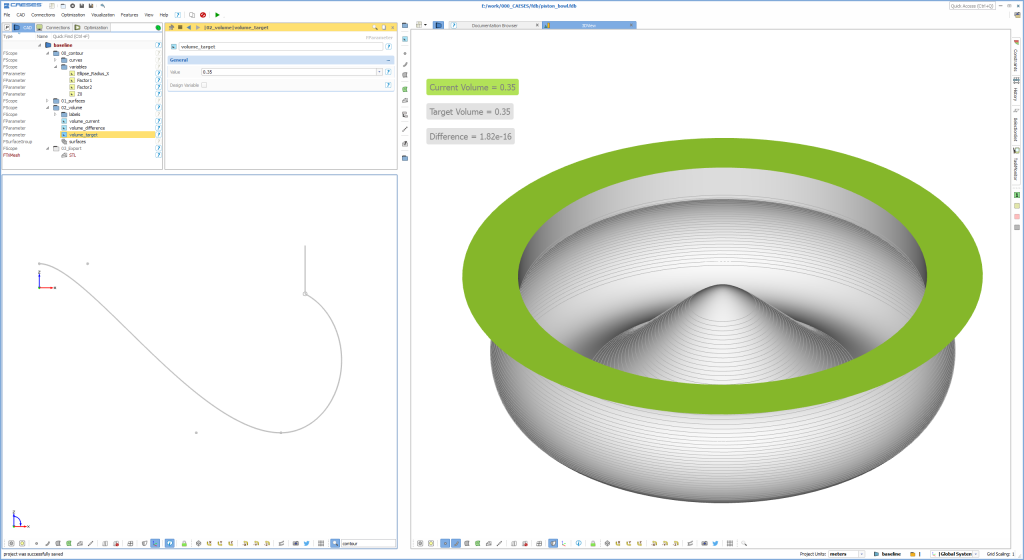

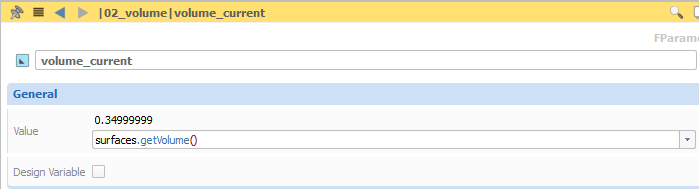

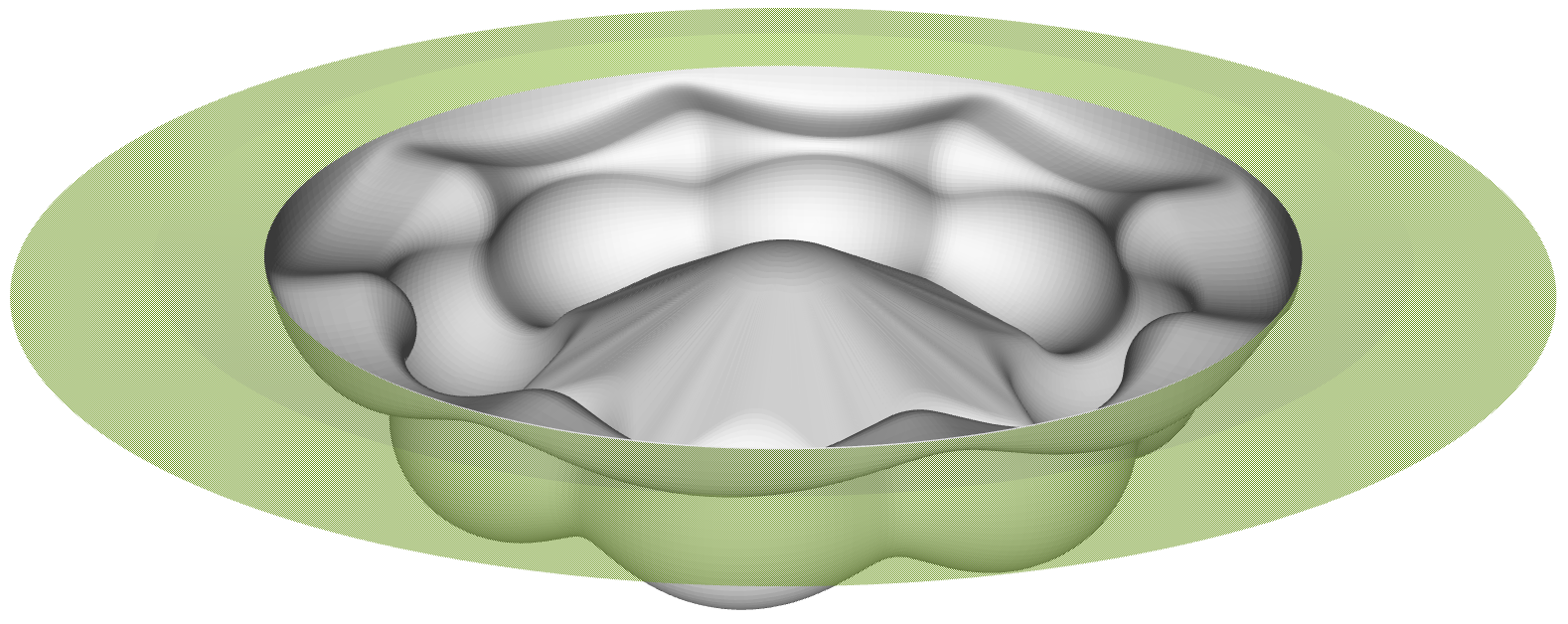

The following screenshot shows a typical piston bowl design in CAESES®. The surface of revolution is created by means of a 2D contour that is basically a set of 3 curves (bspline, ellipse, line). The left window shows the contour design, while the larger window shows the surface plus the information about the current piston bowl volume.

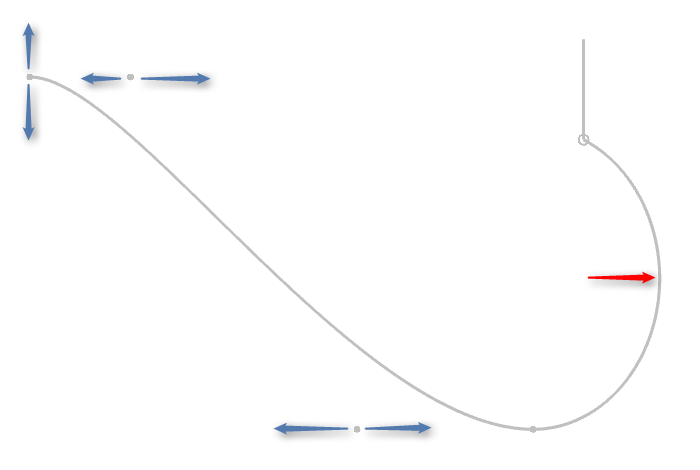

As said before, the compression volume should be a user input, and we need to find a way to consider this in our geometry setup. In this demo example, we have 3 design variables (blue-colored arrows in the next picture) that are connected to the vertices of the bspline curve. The user can change these vertices along the x-direction, as well as the upper two vertices along the z-direction:

There is another free variable that gets controlled by an optimization engine, indicated by the red arrow in the above picture. The optimization engine has access to the current volume of the bowl that is defined by the contour. This is a simple calculation command in CAESES®. As soon as the user changes the control vertices, the optimization is triggered automatically and sets the free variable in a way such that the compression volume is met. This works in a fully automated way without any user interaction, simply as a result of the internal update process in CAESES®.

Animation

As you might have noticed already during our recent blog posts, we really love animations because they much better illustrate what is really going on. We have put together an animation that shows how designs get created where the target compression volume is met for each variant. Just click on the image below to take a look at the animation:

Shape Optimization

As soon as the setup is ready, the automated creation of design candidates within exploration studies or formal optimizations is a natural next step. Our users from the automotive industry typically run large studies of such cases where the simulation for each design is included as well. Additional constraints can also be considered such as the distance of the bowl to the wall etc.

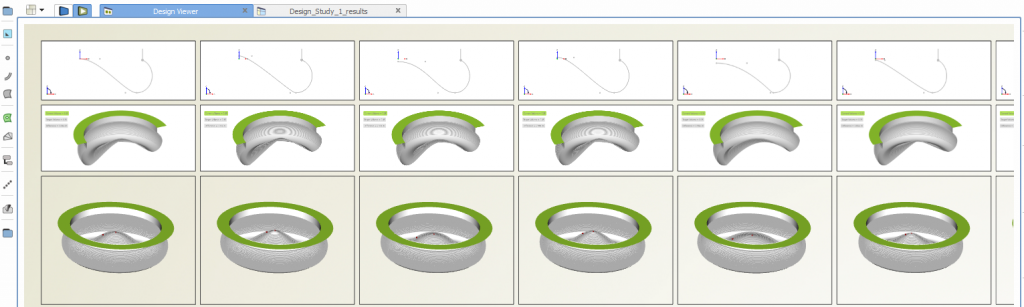

The final screenshot shows the design viewer in CAESES® where the geometries of design variants can be compared in a side-by-side viewer. Just click on it again to watch a very short video.

More Information

There is a nice article with plenty of animation that shows piston bowl design and optimization using CAESES and CONVERGE.

Follow Us

Do you work on similar tasks? What is your experience with it? Feel free to share your thoughts on this blog post. If you are interested in stories like this and in CFD-driven design optimization, then sign up for our newsletter. Don’t worry, we won’t bother you with too many emails. Of course, you can unsubscribe at any time 🙂

Respected sir,

I am Sajil N Sreedharan, doing Mtech thesis in piston bowl design. I need to know more about how this is done. Please do help me in trying this. How can we calculate the bowl volume .

Dear Sajil,

As described in the article, we set up an internal optimization where the objective is a given area (which can be mapped to a volume). If you post your question in the CAESES forum (https://www.caeses.com/forum/) we can probably give you a simple example for such an optimization.

Pingback: Piston Bowl Design and Optimization › CAESES