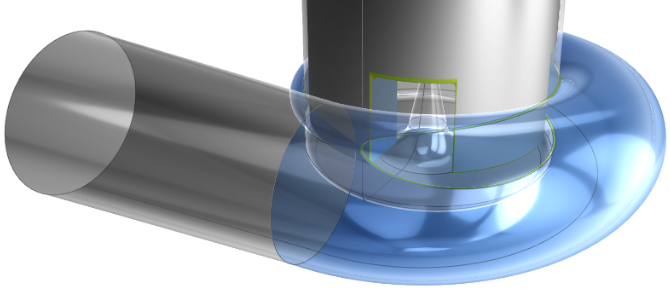

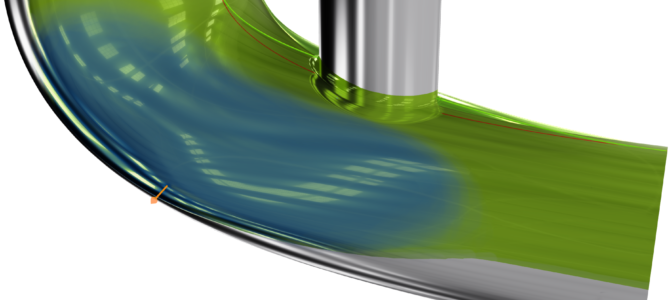

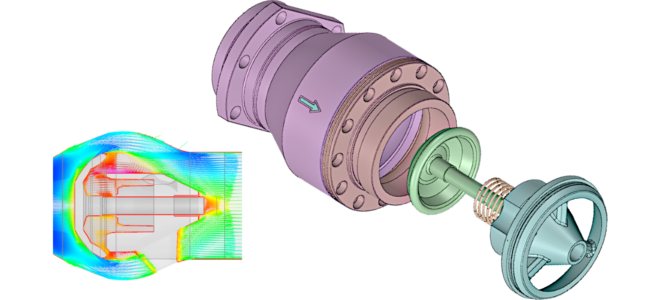

Researchers at the Division of Applied Biomedical Engineering at the Penn State College of Medicine have been using CAESES in combination with CONVERGE as a CFD Integrated Optimization Platform for the development of safer and more efficient ventricular assist devices.