Over the past few years, researchers at the Division of Applied Biomedical Engineering at the Penn State College of Medicine have been using CAESES in combination with CONVERGE as a CFD Integrated Optimization Platform for the development of safer and more efficient ventricular assist devices, see this first blog post from 2018 for a full background.

The overarching goal of these studies is to reduce the size of the pump while reducing the risk of adverse events such as hemolysis, degradation of von Willebrand factor, and thrombus formation. In order to efficiently create a wide range of design variants, the complete flow-path geometry of the pump was parameterized in CAESES. The assessment of the design variants during the optimization process is focused on estimating the susceptibility for adverse effects, initially by looking at volumetric averages of the turbulent energy dissipation (EPS), but has since been augmented by several additional evaluations from the CFD analysis:

- Pressures (across pump inflow/outflow, radial and axial gaps).

- Plasma free hemoglobin (PlHb) production and concentration using an in-house developed EPS-based hemolysis model.

- Strain-rate and an in-house developed strain-rate based thrombus susceptibility potential (TSP) model.

- Wall shear stress.

- Variation of both radial and axial forces and torques on the rotor (pressure and viscous).

Pump Geometry Parameterization

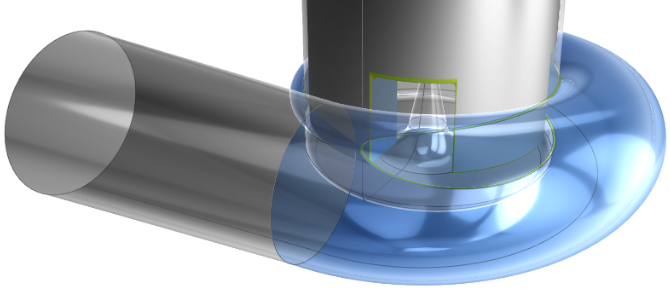

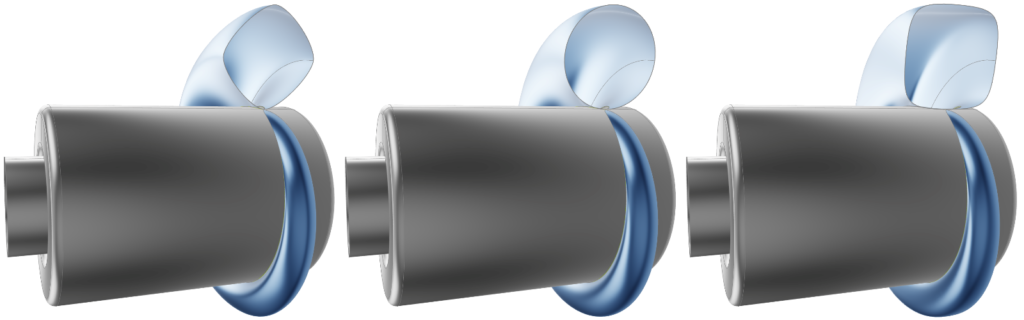

While the first optimization studies were focused on the blades, more and more additional geometry features have been added over time, leading to a complete parameterization of the pump and a much-extended design space for investigation. This includes the toroidal rotor body onto which the blades are attached, which can now be controlled in height, width, and edge fillet radii, as well as the surrounding fluid gaps in axial and radial direction.

The spiral scroll, or volute, is a crucial component in determining the performance of any centrifugal turbomachine. In this case, knowing that the flow leaving the pump is complex and has a tendency to form Dean vortices, various scroll geometries were analyzed to minimize said vortices. The spiral path was prescribed mathematically by entering the (parametric) spiral equations in a generic curve. The cross-sections of the volute scroll were then swept along this guide, always starting with a circular profile – controlled by its radius – and ending with a variable cross-section that can take on a diamond, square, and circular shape – additionally controlled by its width.

Finally, another key feature of the pump is the endcap that is located just opposite of the blades. The profile of the middle spike is of importance, as it was introduced to help guide flow towards the volute. The spike design variables dictate the overall height and base width.

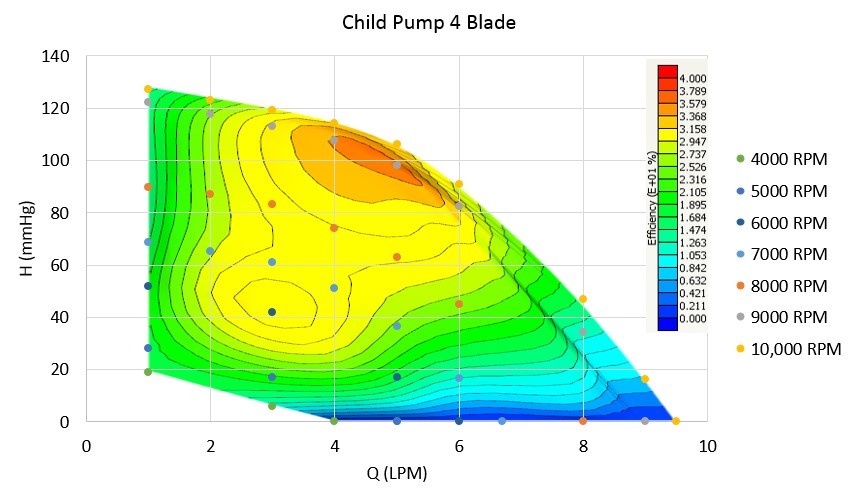

H-Q and T-Q Mapping

Alongside the design variation studies, automated pump performance simulations for head/torque vs. flow (H-Q and T-Q, respectively) mapping of the different pump designs were performed. The CAESES Design Assembler was used to structure the simulation queue while outputting pressure, rotor torque magnitude, and the estimated efficiency (not considering losses), as well as EPS or PlHb estimates in a targeted region in the outflow of the pump. Based on the collected results, 2D H-Q and T-Q performance curves can be plotted. By overlaying results such as pump efficiency or PlHb as the z-coordinate of each H-Q point a 3D surface plot can be generated that shows a more in-depth view of the pump performance.

The results from all these new numerical design studies and optimizations are currently undergoing extensive in-vitro and in-vivo verification and we will make sure to come back with a further update once the results have been peer-reviewed and published.

Learn More

See this overview for the possibilities and capabilities that CAESES offers for medical applications.

Questions?

Please do not hesitate to get in touch with us if you have questions in the context of your specific application. We look forward to discussing it together with you!