Faster simulations, better decisions: a FAST 2025 case study shows how early-stage design space exploration can identify efficient planing hull geometries before committing to CFD.

Faster simulations, better decisions: a FAST 2025 case study shows how early-stage design space exploration can identify efficient planing hull geometries before committing to CFD.

Engineering design has evolved from hand-drawn sketches and wooden splines to CAD, parametric modeling, simulation-driven design, and now Generative AI. Each shift expands creativity, accelerates exploration, and enhances decision-making, transforming engineering into a more intelligent, data-driven, and human-centered process.

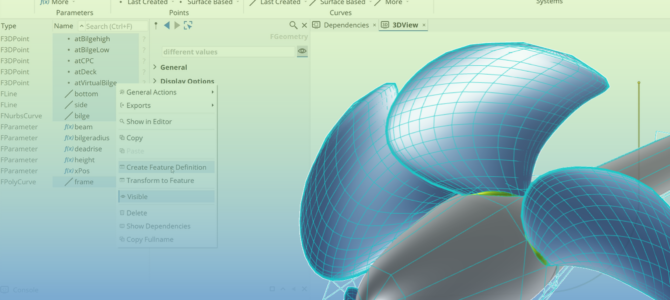

A new era of underwater propulsion is emerging – powered by CAESES. In a bachelor’s thesis at Brno University of Technology, a hybrid toroidal rim-driven propeller was developed for compact underwater drones, combining toroidal blade geometry with rim-driven technology. Using CAESES for parametric modeling and CFD integration, the design achieved higher efficiency, lower noise, and exceptional debris resistance, showcasing how smart automation and simulation-driven design can redefine marine propulsion.

CAESES is packed with powerful capabilities designed to accelerate simulation-driven design, but some of its most impactful features often go unnoticed. In this blog, we spotlight five advanced tools that can help you optimize geometry, enforce constraints, streamline workflows, and push the automation design further.

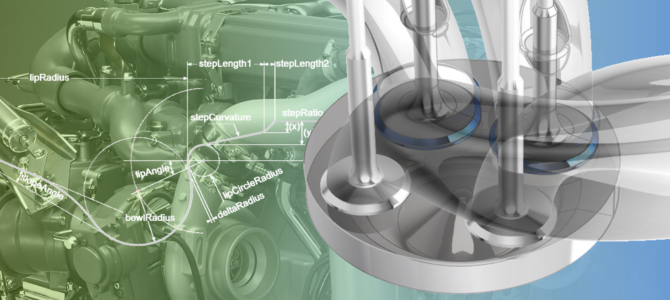

Discover how CAESES speeds up design of piston bowls with parametric modelling, automated optimization, and CFD integration, all in one smart workflow. Watch the video to see how it works whilst discovering how to confidently meet your performance goals.

A demihull of a houseboat has been optimized by studying the influence of bow shape modifications on the vessel’s total resistance. A parametric model was developed and subjected to a RANSE-based multi-objective optimization.

PediaFlow is an implantable heart pump, intended to provide hemodynamics support for infants and young children with heart failure. Cornell University researcher Mansur Zhussupbekov used CAESES to improve the pressure recovery while maintaining biocompatibility.

The research and development project VIT-VI focuses on artificial intelligence (AI) methods and their use in the context of virtual, sustainable aero engine development. The focus is on building and strengthening AI competencies and increasing the use of artificial intelligence methods to enhance productivity in data- and simulation-driven design.

Achieving optimal efficiency and performance is crucial for the design of propellers. A combination of AI and CFD helped win a recent propeller design competition hosted by Daniel Riley, a maker and popular YouTube creator (RCTestflight). Using CAESES and AirShaper we generated two high-performance propellers that demonstrated remarkable efficiency.

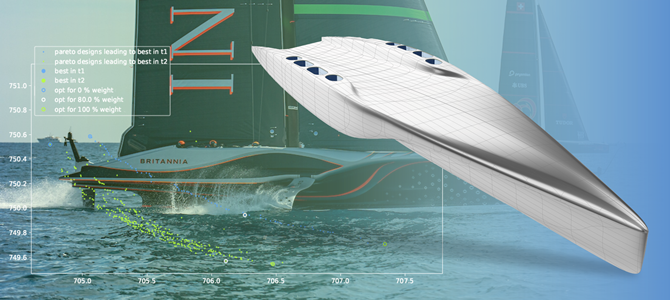

The America’s Cup is not only a fierce sporting, but also an engineering competition. Years of development culminate in two months of intense match racing. Designing the hull of an AC75 presents a complex engineering challenge, with numerous factors to consider.