The research and development project VIT-VI (short for German: “VIrtuelle Triebwerksentwicklung mit Verfahren der künstlichen Intelligenz” | English: “Virtual Engine Development using artificial intelligence methods”) focuses on artificial intelligence (AI) methods and their use in the context of virtual, sustainable aero engine development.

The focus is on building and strengthening AI competencies and increasing the use of artificial intelligence methods to enhance productivity in data- and simulation-driven design.

CAESES offers the possibility to automate design exploration and optimization processes for complex flow-exposed geometries. Predominantly, CAESES is applied to generate robust parametric models and acts as a framework for automated design studies by coupling to fluid-dynamic solvers, whose results are used to optimize the shape – all within a single environment. CAESES does already provide machine learning (ML)-based solutions, such as response surface models (RSM) or principal component analysis (PCA), which are scheduled to be expanded within the VIT-VI research project. Here, the focus will be to implement new AI-, ML- and Deep Learning-based methods to reduce time and complexity in the modeling process and increase the efficiency of conventional optimization processes.

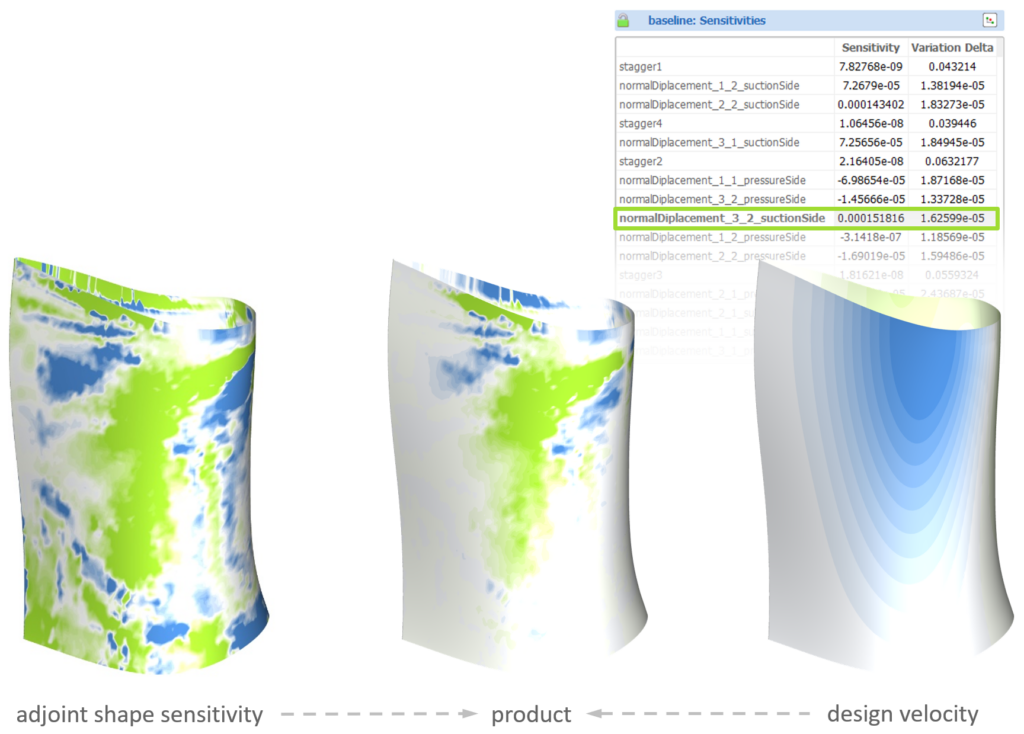

Adjoint Optimization

Adjoint methods have been implemented in CAESES with the goal of improving the efficiency of the optimization process by integrating adjoint sensitivity/gradient data into the workflow. Based on earlier studies, the existing functionality to determine so-called parametric sensitivities was improved and tested to ensure accuracy during the optimization. These “parametric sensitivities” connect the shape sensitivities from the adjoint CFD solver with the geometrical design velocities in CAESES, which in turn describe the model surface displacement gradients for each design parameter.

New features were created to provide customers a quick and easy setup when introducing adjoint methods in their optimization process and a functionality to weigh the parametric sensitivities to focus on critical regions of the geometry was implemented, further reducing the number of iterations and thus computational resources.

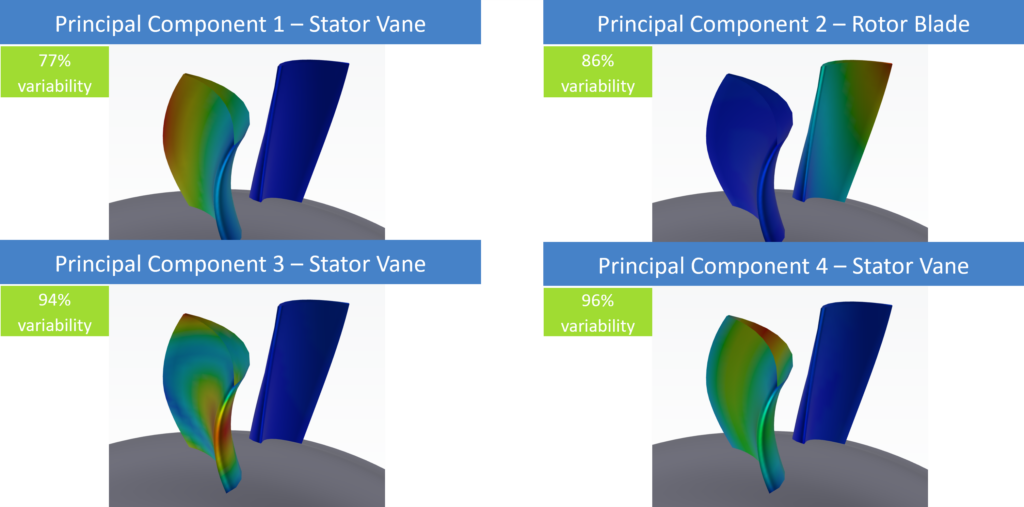

Principal Component Analysis

Another way of reducing the need for expensive computational resources in an optimization is to reduce the complexity of the geometry that needs to be optimized. In the scope of the VIT-VI project, research on how to expand the existing principal component analysis (PCA) tool in CAESES is carried out in collaboration with the BTU (Brandenburgische Technische Universität) and Rolls-Royce by implementing and testing new algorithms to determine the principal parameters, as well as alternative methods to generate the back-transformation from the principal component space to the original CAD parameter space.

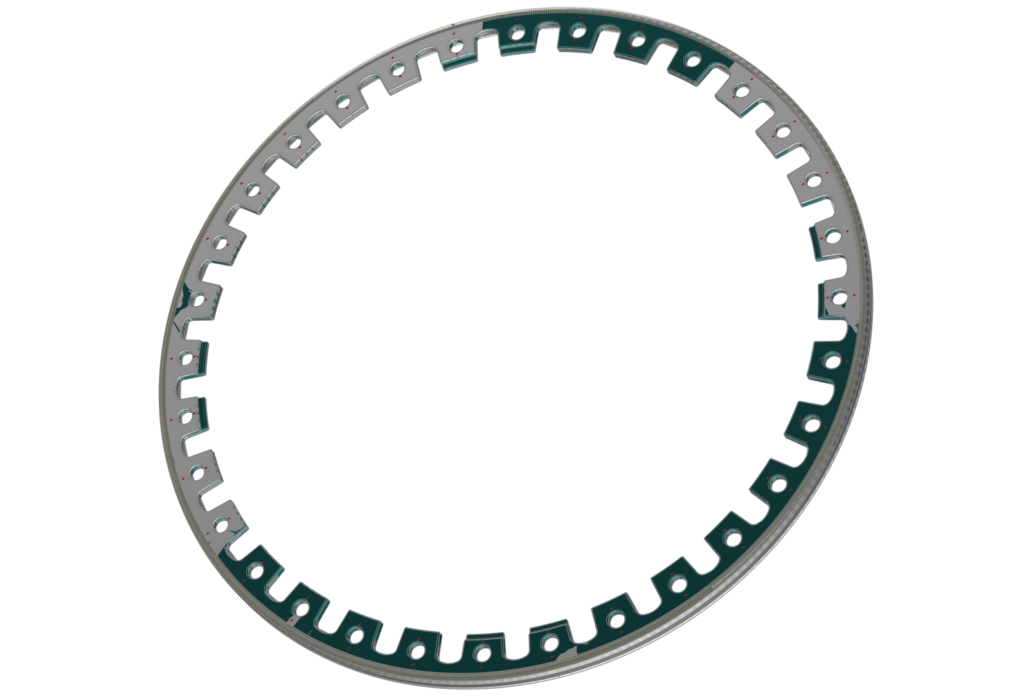

Balancing Process

Focusing on the acceleration and improvement of modeling processes, research was conducted in collaboration with Rolls-Royce to incorporate manufacturing deviations into the design process of complex geometry, with the specific goal of digitalizing the rotor balancing process.

Workflows have been developed to easily import measurement data from manufactured components and directly link it to morphing-based modifications of the CAD geometry model. Future research will involve further investigations on more complex morphable shapes, containing larger data sets, and utilizing the morphed geometries for establishing a workflow to virtually run the balancing process. This aims at significantly reducing time and costs during the assembly of aircraft turbofan engines.

In close exchange with Rolls-Royce, data on the existing morphing methods can be collected and applied to further optimize Radial-Basis-Function (RBF)-morphing techniques and establish new workflows to connect large data sets with morphing methods in CAESES. The measured manufacturing deviations are utilized to train a machine learning model and expand the data set to derive a statistical pattern, from which another ML model will be trained to optimize the balancing process.

AI-based Chat Assistant

The development of an AI-based chat assistant in CAESES will help navigating through the GUI and offering optimized search algorithms, so that users can quickly find case-specific information inside the CAESES documentation. Future research will include implementing, evaluating, and testing different methods to introduce AI-based navigation and assistance in the daily routine of engineers working with CAESES. In addition, further research will include automated feature code generation to help users write complex scripts without a deep background knowledge of the feature programming language. Another part of this research will consist in collecting and utilizing data from typical geometry modeling processes to train ML models to suggest appropriate modeling steps and operations during the creation of parametric models in CAESES.

Outlook

In the later stages of VIT-VI, research on introducing interfaces to implement reduced order models (ROMs) in the optimization process in CAESES is planned, as well as expanding the applicability of surrogate models for larger data sets. Additionally, interfaces will be provided for users to add custom surrogate models and thus offer even more freedom in developing custom optimization workflows.

Further research will include offering AI-based real-time flow field visualization to quickly analyze shape variations without the need to run additional CFD calculations.

We are excited to be part of the VIT-VI project and are looking forward to a fruitful and interesting collaboration with Rolls-Royce Deutschland, BTU, TU Berlin (Technische Universität Berlin) and THB (Technische Hochschule Brandenburg), as well as diving deep into the possibilities to implement AI-based methods to support engineer’s daily routines.

Funding

The project is funded by the program for the promotion of research, innovations, and technologies of the state of Brandenburg (ProFIT Brandenburg) through the Ministry of Economic Affairs, Labor, and Energy of the state of Brandenburg (MWAE) and supported by the Investment Bank of the state of Brandenburg (ILB). The funding comes from the European Regional Development Fund (EFRE) and the state of Brandenburg. The VIT-VI research project is co-funded by the European Union.