New Optimus integration with CAESES further strengthens automated design optimization processes

Leuven (Belgium) / Potsdam (Germany), February 6 – 2019 – Noesis Solutions, the developer of Optimus and id8, and FRIENDSHIP SYSTEMS announced the release of a new direct integration with CAESES®. By automating the creation of simulation-ready geometries and the related engineering simulations, Optimus can evaluate a vast number of design variants in a limited time frame. This further extends the engineering insights delivered by simulation, enabling teams that use CAESES to identify leading candidate designs offering benchmark performance.

Design Optimization based on Parametric Geometry Models

FRIENDSHIP SYSTEM’s geometric modeling technology is used by engineering teams whose ultimate goal is to design optimal flow-exposed products. Compared to traditional CAD tools, the creation of geometry variants using CAESES can be fully automated and is 100% robust, thanks to the dependency-based modeling approach. All generated geometries are clean and watertight, which is essential for running design studies that involve meshing and CFD simulation software on HPC clusters. At the same time, CAESES geometry models help engineering teams save computational time as they have fewer design parameters, while design constraints can be built directly into the CAESES geometry model itself.

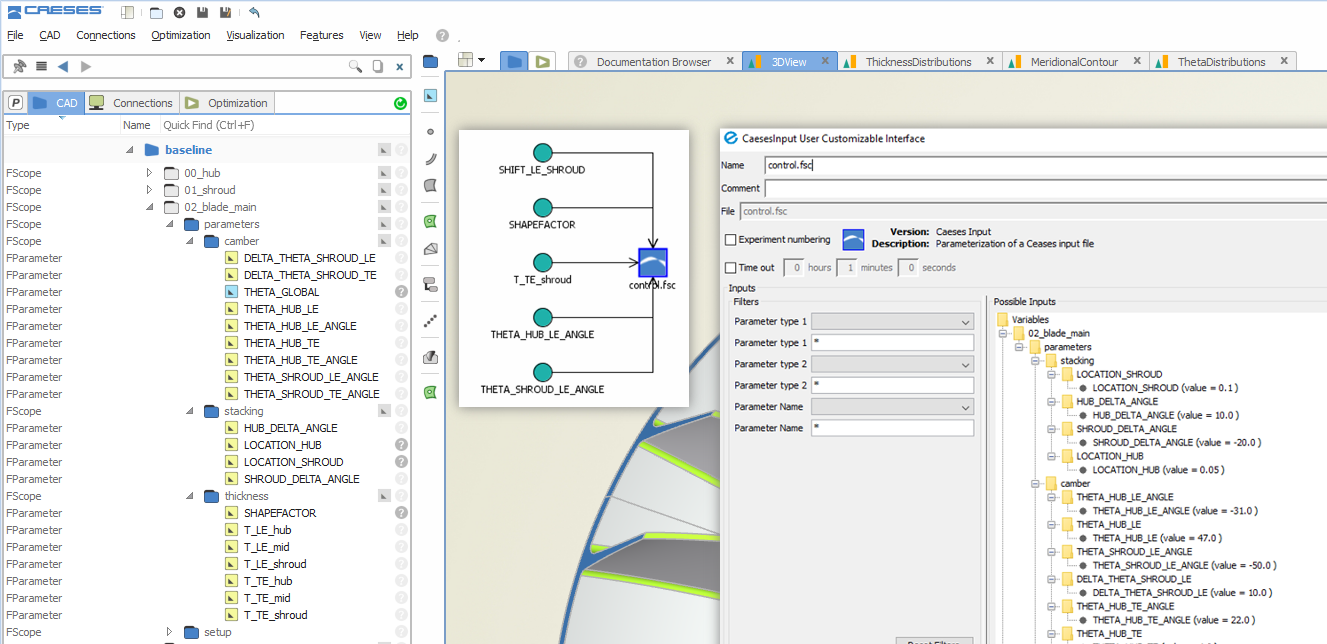

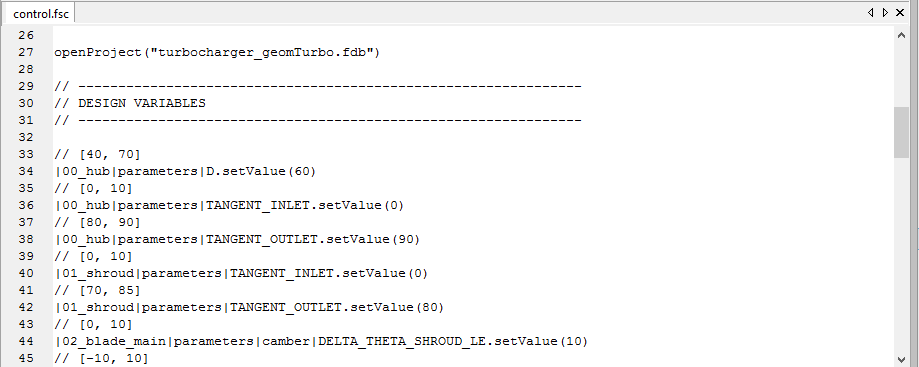

The direct integration between Optimus and CAESES enables users of both software products to automate the creation of geometry variants with just a few clicks. By running CAESES in batch mode, Optimus triggers the generation of geometry variants in the background with no graphical user interface involved. CAESES users only need to set up a reference geometry model, along with a set of design variables that control the geometry shape.

Using Optimus, design engineers typically perform Design of Experiments (DOE) to define a virtual experiment plan that acquires the most relevant design information possible with minimum simulation effort. Response Surface Modeling (RSM) condenses complex simulations to help design engineers fully understand the unexplored design space potential up-front. Finally, Optimus manages an automated and coordinated search to identify those design parameter values that meet a combination of multiple (often competing) performance targets. Throughout the process, Optimus consistently takes into account design constraints imposed by manufacturing realities and stringent regulatory and standardization requirements.

Identifying the Best Product Design in the Shortest Time Possible

“Optimus is known for capturing and automating simulation workflows without any programming skills. The new direct integration with CAESES makes it easier for Optimus users to parameterize any virtual design model and automate the execution of the entire simulation process, including the creation of robust geometry models” said Naji El Masri, Noesis Solutions CEO. “This proven process frees engineers from repetitive tasks, enabling them to identify better performing designs much faster than through conventional methods. It strengthens manufacturers’ competitive edge by delivering the best product design in the shortest time possible while saving tremendously on engineering, manufacturing and material cost.”

“The new direct integration with CAESES makes it easier for Optimus users to parameterize any virtual design model and automate the execution of the entire simulation process, including the creation of robust geometry models”

— Naji El Masri, Noesis Solutions CEO

“With these new CAESES integration capabilities in Optimus, our joint users can immediately benefit from both solutions without scripting a single line. All the parameters from a CAESES model are directly accessible in the Optimus GUI, and can be controlled for running large design studies with parametric CAESES models. It’s amazing how easy this works, and hence will attract more engineers to introduce formal shape optimization workflows.” said Dr. Stefan Harries, the CEO from FRIENDSHIP SYSTEMS.

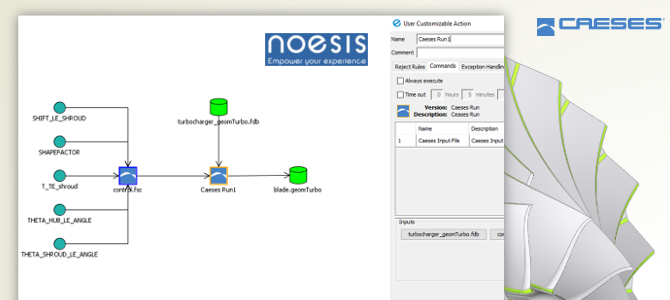

Video: Example Turbocharger Impeller

There is a detailed recording which explains how to automate CAESES® in Optimus. In this video, CAESES® and NUMECA tools are automated for design exploration and shape optimization of a turbocharger impeller. CAESES® provides the geometry variants for the impeller, where all generated geometries are exported using a custom *.geomturbo format.

About FRIENDSHIP SYSTEMS

FRIENDSHIP SYSTEMS is a German software company with its core team based in Potsdam, Germany. FRIENDSHIP SYSTEMS develops CAESES®, a flexible CAD platform for the creation of simulation-ready geometries. CAESES® targets simulation engineers and anyone who is interested in intelligent surface design for automated design explorations and shape optimization.

With many years of experience in the field of flow-related shape optimization and its proven CAESES® software platform, FRIENDSHIP SYSTEMS provides solutions for virtually every problem and bottleneck that customers might encounter when setting up flow-related design studies.

For more information about FRIENDSHIP SYSTEMS and CAESES, please visit the product pages and company pages. If you have further questions, please use this form to get in touch with us.

About Noesis Solutions

Noesis Solutions is an engineering innovation partner to manufacturers in engineering-intense industries. Specialized in solutions that enable Objectives Driven Draft-to-Craft Engineering processes, its software products and services help customers adopt a targeted development strategy that resolves their toughest multi-disciplinary engineering challenges.

This Engineer by Objectives strategy entails an automated approach that streamlines engineering processes to manage the growing complexity of today’s engineering challenges efficiently. In addition, interactive design space visualization allows engineering teams to make informed decisions faster – empowering them to form & transform ideas into products that outsmart the competition

Noesis Solutions operates through a network of subsidiaries and representatives in key locations around the world. For more information, please visit www.noesissolutions.com.

Noesis Solutions Press Contact:

Kirsten Cabergs

Phone +32 16 31 70 40

kirsten.cabergs@noesissolutions.com

Interested in Testing?

If you like to test this Optimus integration of CAESES®, please get in touch with us.

Follow Us

If you are interested in topics like this and in simulation-driven design optimization in general, then sign up for our newsletter. Don’t worry, we won’t bother you with too many emails. Of course, you can unsubscribe at any time 🙂