The America’s Cup is not only a fierce sporting, but also an engineering competition. Years of development, and the concentrated effort of over 100 team members, culminate in approximately two months of intense match racing. As in the previous installment, the current 37th America’s Cup is sailed with AC75s – high-performance foiling monohulls that are very demanding to sail and capable of upwind and downwind speeds of 2.5 and 3.5 times the wind speed, respectively.

Designing the hull of an AC75 presents a complex engineering challenge, with numerous factors to consider, especially in terms of aerodynamic efficiency in conjunction with the rig and sail package. Its optimization primarily focuses on maximizing this efficiency, while also accounting for various operational modes: take-off, high-speed foiling aerodynamics in different wind speeds and headings, and touch-down hydrodynamics, when the hull makes contact with the water while impacting waves.

The AC75 class rules impose strict guidelines that heavily influence hull design, covering parameters like dimensions, volume distribution, and hydrostatics. While standardized components like the foil cant system remain fixed, their positioning adds geometric constraints that designers must consider. The hull is subject to tight tolerances, allowing little deviation. Designers must balance these restrictions, while optimizing for aerodynamic efficiency, stability, and hydrodynamic resistance.

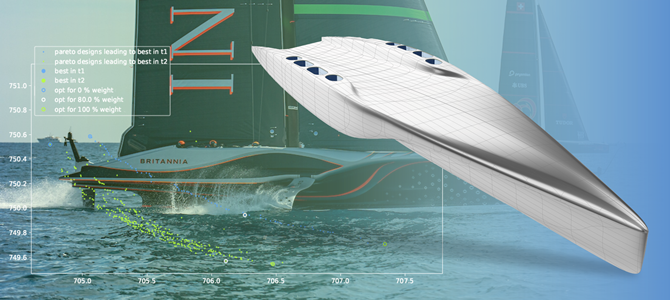

INEOS Britannia tackled the AC75 design challenge using CAESES, alongside expert modeling and CFD know-how from FRIENDSHIP SYSTEMS, by developing a sophisticated parametric model of the hull capable of exploring a wide-ranging design space. This model incorporated all relevant class rule constraints and pre-processing steps required for CFD simulations. After generating sufficient high quality CFD data, machine learning algorithms were used to predict forces during take-off, touch-down, and aerodynamic efficiency in foiling mode, based on flight height and trim in different wind, waves, and heading conditions.

The subsequent optimization process focused on generating the fastest, rule-compliant hull shapes for various conditions. This data-driven approach revealed trends in how the optimal hull shape changes in different scenarios. Rather than aiming at winning every race, the objective was to design a robust hull that maximized the chances of winning the competition, based on the most likely distribution of conditions to be encountered.

A wide range of additional factors, such as foil performance, cant angle, heel, sail trim, and others, must be meticulously accounted for when predicting the time on course for a specific design variant and environmental condition. Accurate CFD simulations and comprehensive data analysis are essential to identifying the optimal winning shape. The expertise and in-depth knowledge at INEOS Britannia are exceptional, and it was a privilege to collaborate with their team of experts on such a complex and demanding project.

According to INEOS Britannia’s chief designer, Dr Martin Fischer, this method of design and optimization has been crucial to their development success, as described in his presentation at the CAESES User Conference 2024. And it has already paid off for INEOS Britannia. On October 1, 2024, during Day 5 of the Louis Vuitton Cup Final, Britannia set a new speed record for the AC75 class, reaching 55.5 knots (102.8 km/h or 63.9 mph). Additionally, on October 4, they won the Louis Vuitton Cup and are now challenging the defending champion – Emirates Team New Zealand – for the 37th Americas Cup.

To get some more details about how INEOS Britannia has used CAESES to design their AC75 hull, see Martin Fischer’s presentation from the CAESES User Conference.

We wish INEOS Britannia all the best for their upcoming races as they take on the defenders in the America’s Cup!