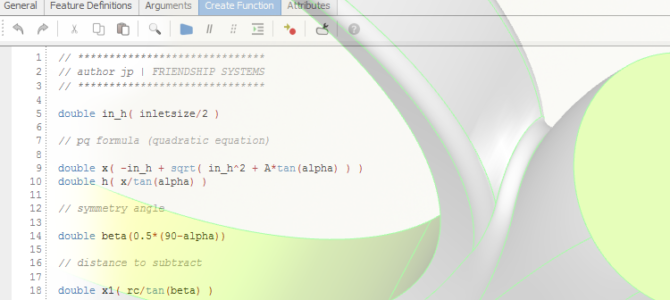

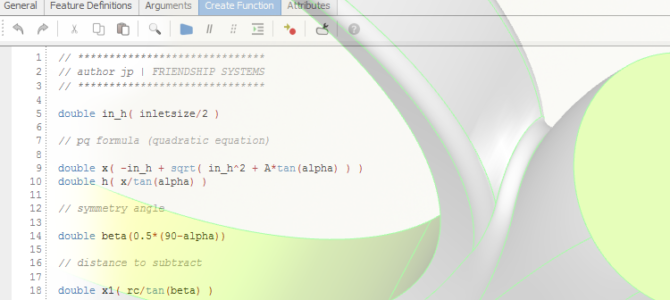

Geometry scripting is really a cool thing! It allows you to create highly customized geometry parts – parts that are often impossible to create with the typical capabilities of a graphical user interface (GUI).

Geometry scripting is really a cool thing! It allows you to create highly customized geometry parts – parts that are often impossible to create with the typical capabilities of a graphical user interface (GUI).

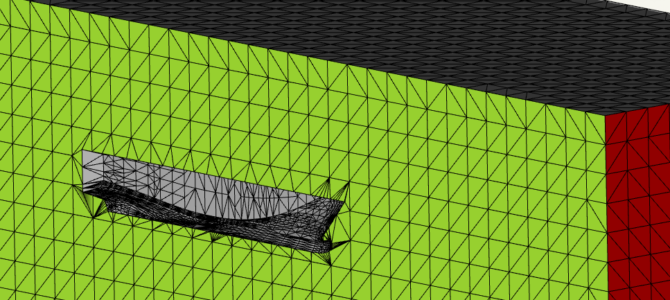

From time to time we receive NAPA IGES files from our maritime customers which are basically an assembly of often hundreds of single surface patches. The question is then: How can we quickly create a watertight, box-like flow domain for…

For the exchange of propeller geometry data, CAESES® offers the possibility to import and export files using a format that is called PFF (Propeller Free Format). We support the PFF format since these files are widely used by ship and…

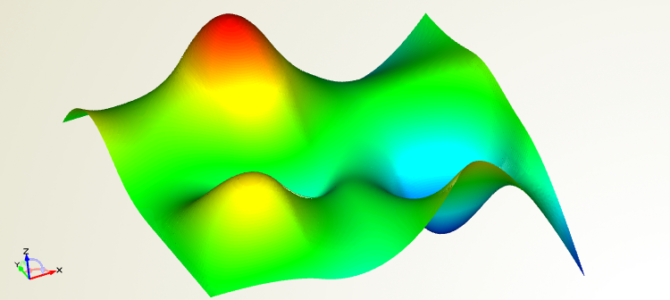

Response surfaces, also known as surrogate models or meta models, are nowadays often used whenever the evaluation of a function is not directly possible or simply too expensive. In the context of engineering and simulation, a typical application is the…

What exactly is CAESES® and what does it? This short interview with one of the founders from FRIENDSHIP SYSTEMS, Dr. Stefan Harries, will give you some quick insights: Q: What is the most important functionality that CAESES provides? “Most…

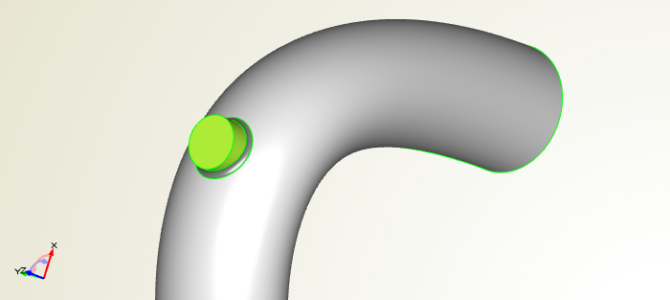

When you design high performance engines in the field of motors sports, you can find a variety of complex duct geometries, air intake manifolds and other weird-shaped components. In order to increase the horse power of the engine, you can…

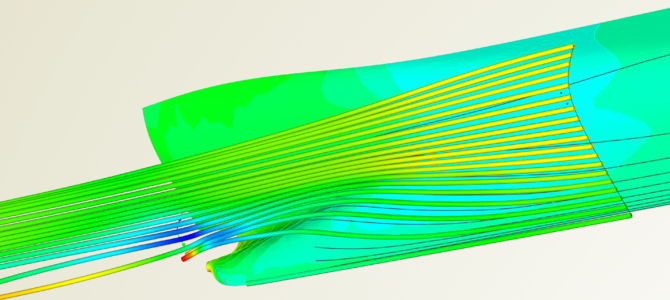

CAESES® comes with a set of CFD post-processing features, which are mainly used to quickly assess and compare the flow behavior of the generated design candidates. The visualization of 3D streamlines is a standard procedure of CFD engineers to get…

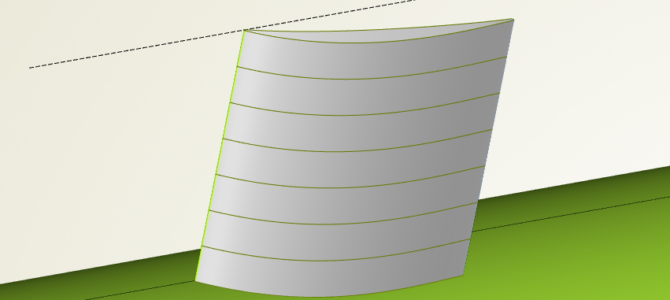

Do you design turbomachinery blades in CAESES® and you want to make use of ANSYS TurboGrid for meshing the variable geometry? Then check out the following quick guide which shows you the export procedure. It’s super fast and easy! Such…

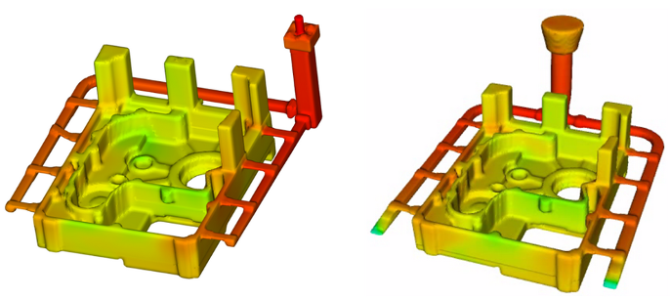

Our partner Flow Science recently published an interesting article about the runner system optimization with FLOW-3D Cast and CAESES®. This case study comes with a set of nice and illustrative pictures plus some details about the optimization results. For us,…

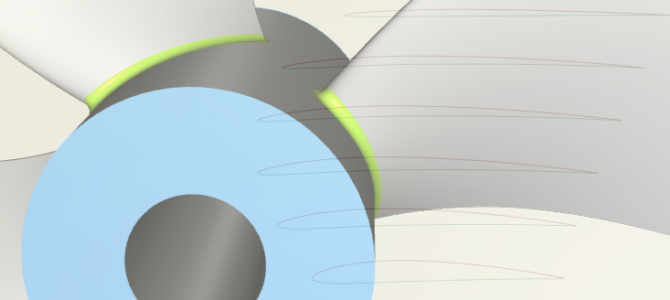

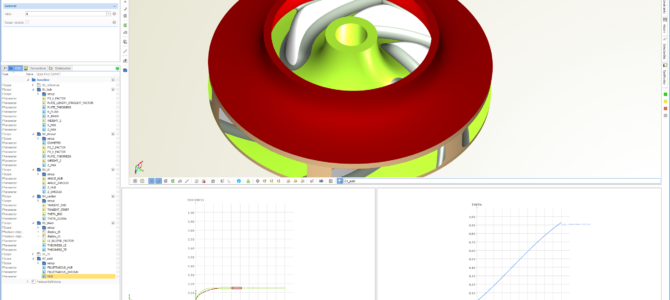

For the CFD-driven shape optimization of water pumps with shrouded impellers, it is crucial to have an efficient variable geometry model with a set of relevant parameters (“design variables”). Let’s briefly illustrate and outline the modeling process of a typical…