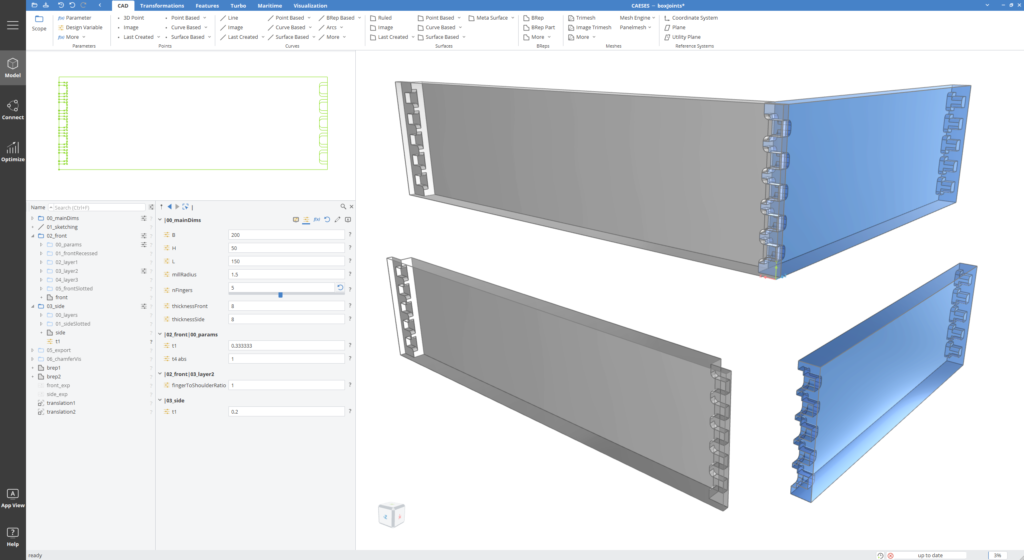

When our colleague Heinrich is not supporting our customers or working on R&D projects, he likes to spend his free time making things. So when he encounters a challenge that might benefit from a convenient parametric approach, CAESES is an obvious choice. Just like this time, when he set out to create a bunch of wooden drawers.

Here is Heinrich’s explanation of his approach:

“I wanted to be able to quickly manufacture wooden boxes and drawers in various sizes. Typically, with a CNC mill, this requires to manually remove additional material from the corners since the milling tool can’t get all the way into sharp corners. A hidden finger joint allows to hide this shortcoming from the eye, while still making for a very strong joint with lots of cross-grain surface area for glue-up. The hidden geometry features are surprisingly complex — especially when aiming for variable box sizes and different stock thicknesses. While they might not be visible, the right number and sizing of fingers is very important to ensure a strong joint. At the same time, clearances need to be fine-tuned to ensure just the right gap sizes for a good glue-coverage. Exactly what a parametric model could provide. So using CAESES was a no-brainer.”

Questions

Please do not hesitate to get in touch with us if you have questions in the context of your specific application. We look forward to discussing it together with you!