The engineering company CFD Schuck offers the optimization of oil cooling systems for electric motors. In an example that can be found on their website (German), 40 design candidates are automatically generated and analyzed using CAESES and the SPH software PreonLab. A short English version of the article is given below.

The cooling of electric motors plays an important role for many engineering tasks of these components. Modern simulation methods provide the possibility to design cooling systems for specific operating conditions in a fast and comprehensive way.

CFD Schuck has now developed an efficient method to optimize the oil spray cooling of the end windings by combining and automating a set of specialized software tools. During the optimization, a variety of different design configurations are investigated in order to find the optimal cooling situation. Typical design parameters are the number and the diameters of the nozzles, but also the slope and position relative to the end windings. In addition, one has to take care of the oil flow-rate and the end windings temperature.

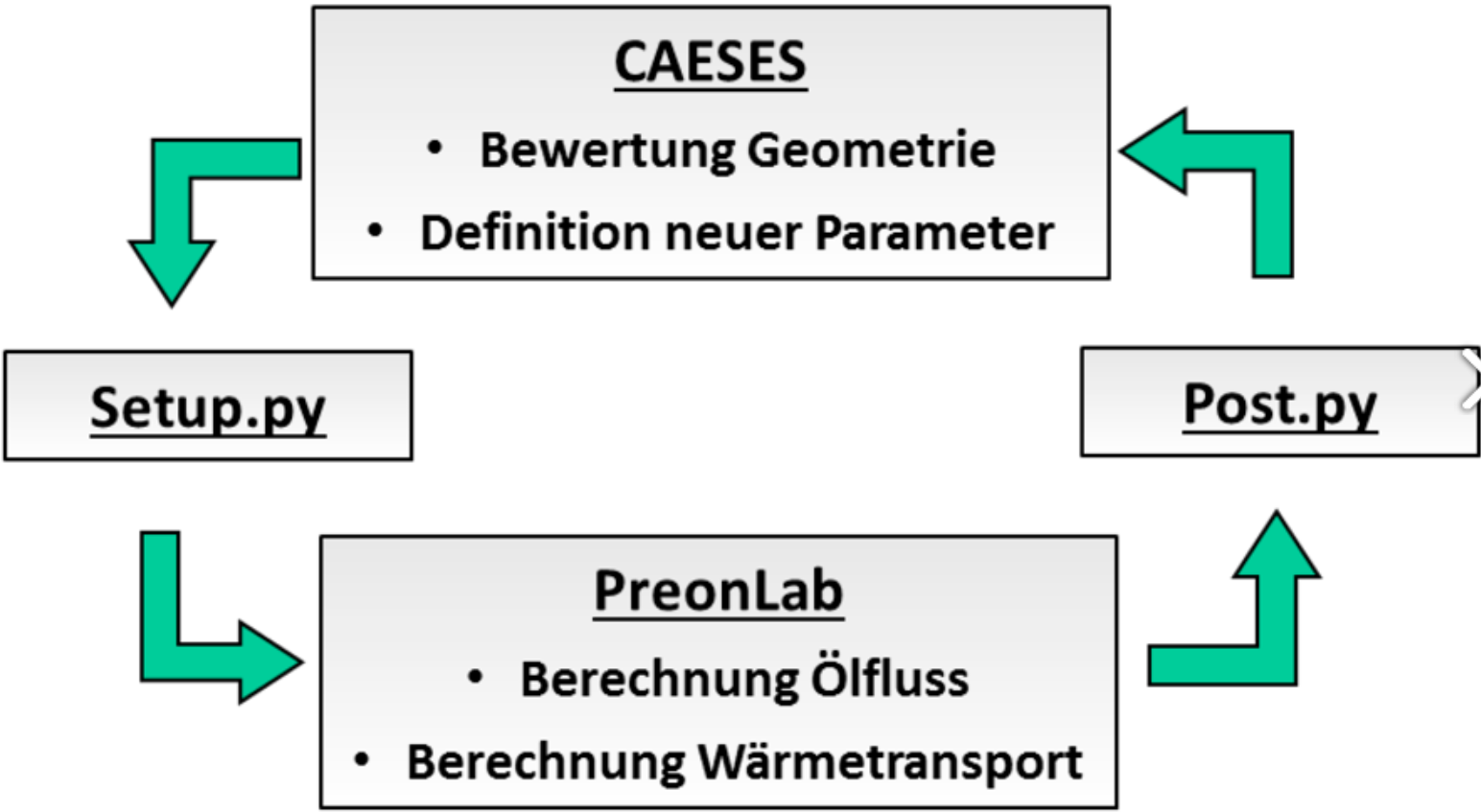

For the CFD analysis of the oil flow and the cooling, the SPH software PreonLab is used. The optimization itself is then conducted by the software CAESES. The workflow also contains a set of Python routines for the geometry generation, the model setup and for the assessment. In the latest optimization project that was run recently, 40 design variants were created and automatically analyzed within 3 days.