MORE THAN 150 ORGANIZATIONS WORLDWIDE RELY ON CAESES

By using CAESES, we could massively bring down our turbine design cycle from several months to only a few weeks.

We launched a pilot project with Friendship Systems to evaluate CAESES in May, it helped us solve a time-critical task in July and it became a design tool by October. By then we had created flexible and robust parametric models for complex parts, enabling us to optimize in design spaces we had previously not been able to explore.

In our experience, using CAESES for creating parametric models was MUCH faster and easier than with our traditional CAD tool – hours versus weeks! For complex geometries, the traditional CAD tool was not the optimum solution because when creating variants we experienced a lot of infeasible geometries, whereas in CAESES we had almost 100% success. At Sirehna, CAESES has become an indispensable tool for conducting comprehensive shape optimization studies in an automated CFD-driven design process.

Before introducing CAESES we ran about one hundred RANSE simulations per year. On the basis of CAESES we are now able to undertake several ten thousands of viscous simulations every year with no additional effort. This gives us an exceptional insight for key product decisions that we would not be able to generate without CAESES.

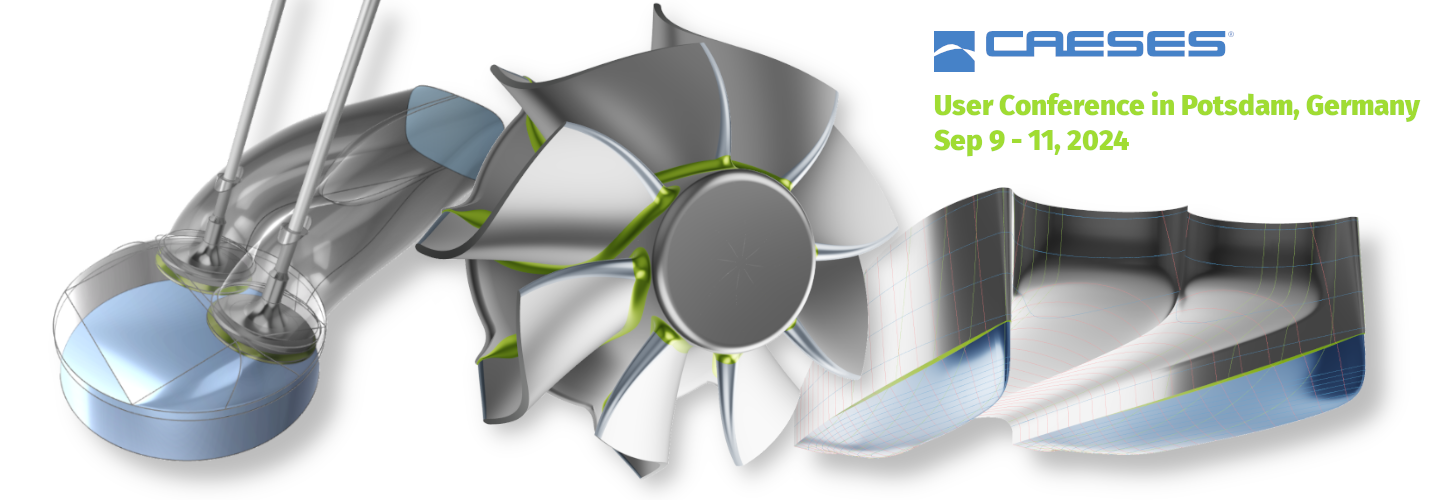

WHAT IS CAESES?

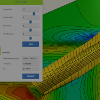

Geometry Modeling

CAESES® foundation is a powerful and flexible parametric 3D modeler. The main purpose: Robust variable geometry with fewer parameters.

Simulation-Ready

Create a clean and robust parametric geometry that is ideal for automated meshing and analysis.

CFD Automation

Integrate, launch and control your simulation runs. Let it be your flexible GUI for process automation incl. 3D post-processing.

Optimization

CAESES® offers integrated methods for automated design explorations and shape optimization.

Shape Deformation

Optimize imported geometries by using the shape deformation and morphing techniques of CAESES.

Powerful Scripting

CAESES® is a command-driven platform that can be fully scripted and customized. Includes batch mode capabilities.

Adjoint CFD

Accelerate your shape optimization process by mapping the results of an adjoint flow analysis to the geometry parameters.

Custom Templates

Get your flexible CAESES model in just a few days! Customized to your needs and easy to use. No CAESES expertise required.