A New Era of Propulsion Innovation – Powered by CAESES

Underwater drones, commonly known as Underwater Unmanned Vehicles (UUVs) or Remotely Operated Vehicles (ROVs), are transforming marine research, offshore energy, and rescue operations. Yet, designing propulsion systems that meet the growing demands of these applications remains a major engineering challenge.

In a recent bachelor’s thesis, Tomáš Jakuš of Brno University of Technology explored a new approach: combining toroidal and rim-driven propeller technologies into a hybrid design. Using advanced parametric modeling and simulation, this novel propeller promises higher efficiency, lower noise, and greater debris resilience – a perfect match for the complex tasks facing next-generation UUVs.

At FRIENDSHIP SYSTEMS, we’re proud that CAESES supports innovative engineering like this, enabling smarter, faster design of cutting-edge marine propulsion systems.

The Design Challenge: Powering a Drone for Extreme Environments

Picture a drone navigating the treacherous depths of the world’s second deepest flooded pit cave, where space is tight, battery power is limited, and debris poses constant hazards.

This project targeted exactly that scenario. The propeller design had to:

- Fit within a compact 60 mm diameter

- Provide equal thrust in forward and reverse for manoeuvrability.

- Maximize energy efficiency for long missions

- Allow debris to pass safely, minimizing the risk of entanglement

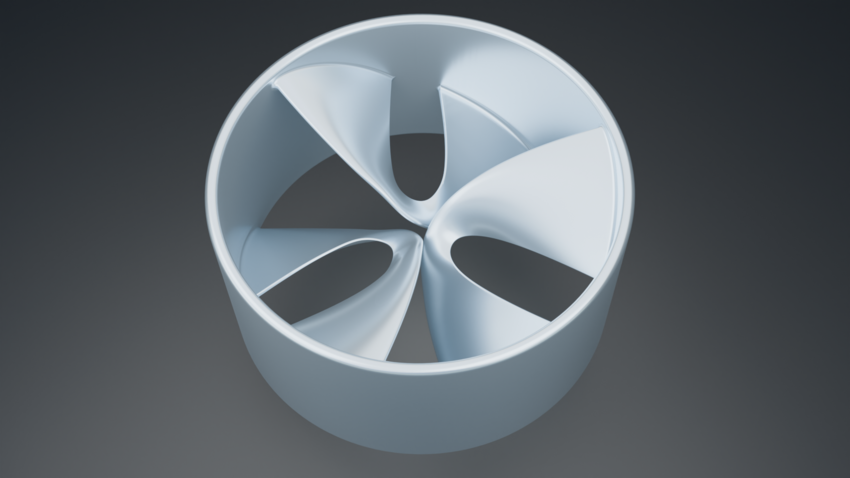

The Solution: A Hybrid Toroidal Rim-Driven Propeller

Toroidal geometry

Loop-shaped blades eliminate tip vortices, leading to less energy loss and less noise. Inspired by innovations like MIT’s toroidal drone propeller, toroidal designs can substantially improve efficiency.

Rim-driven thruster

The blades are mounted on a rotating outer ring, simplifying the overall arrangement and allowing debris to pass through easily, enhancing its reliability in harsh underwater environments.

The hybrid design integrates these features: a toroidal blade form powered by a rim drive. The goal? Aiming to reduce drag and improve bidirectional thrust while simplifying assembly and enhancing resilience to fouling and debris.

Engineering the Concept – Powered by Parametric Modeling and CFD

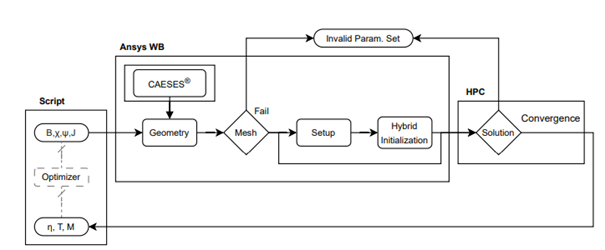

Workflow Overview

CAESES generates geometry variations using design parameters like blade count, centerline angle, stagger angle, and advance ratio. These variations are then transferred to Ansys Workbench via the API, allowing for automated meshing, simulation setup, and hybrid initialization. The simulation is run on an HPC, evaluating thrust, torque, and efficiency. The results are then transferred to the optimizer, which refines the design. If a set of design parameters leads to a null solution, it is flagged as invalid. This automated pipeline reduces manual workload, accelerates design exploration, and ensures only feasible, high-performing designs are selected.

Design Modeling with CAESES

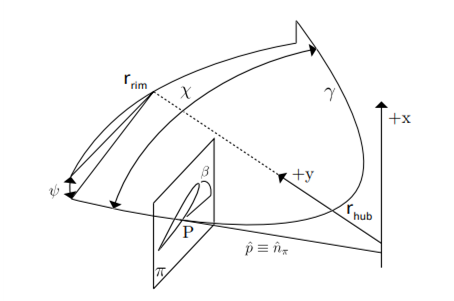

A fully parametric model of the propeller geometry was created, with key variables such as:

- The blade centerline was defined as a quadratic curve, spanning a defined angle (χ) between its end points on the rim.

- The stagger angle (ψ) was introduced to define a tandem-like blade configuration by adjusting the centerline rotation.

- The cross-section of the blade was modeled using a NACA 0021 symmetric airfoil, selected for its balanced performance in both forward and reverse flow operation.

- Additionally, traditional design variables included the number of blades (B) and the advance ratio (J).

Using CAESES, the design space was explored efficiently allowing geometry variations to be linked seamlessly with simulation workflows.

Simulation with Ansys Fluent

The parametric model was incorporated into Computational Fluid Dynamics analysis, utilizing Ansys Fluent simulations of fluid flow, turbulence, and cavitation potential for detailed performance analysis. The setup had been optimized throughout the operating conditions with mesh independence and grid refinement studies demonstrating accurate, reproducible results.

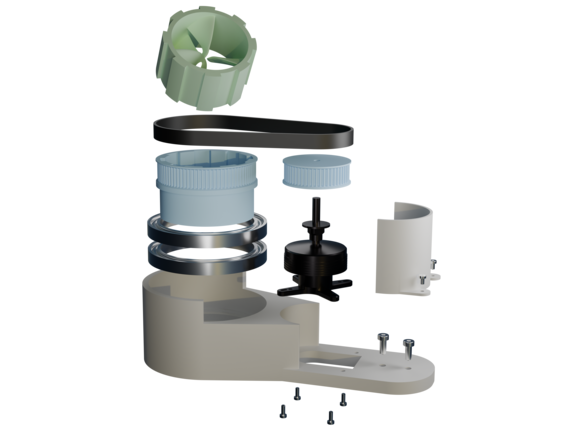

Physical Testing

Following the virtual design process, a physical prototype was constructed and tested in a tank environment in a controlled setting with sensors measuring thrust, torque, and power draw. The testing results confirmed that the hybrid propeller had more thrust and was more efficient than predicted; and there was also excellent bidirectional thrust, confirming the thrust performance projected in the simulation.

Results at a Glance

|

Feature | Hybrid Propeller | Conventional Small UUV Propeller |

|

Efficiency | Up to 28% (bi-directional) |

~20% (only one-directional thrust) |

|

Debris Tolerance | Excellent (open centre) | Poor (central shaft prone to fouling) |

|

Mechanical Complexity | Low (no shaft, compact motor) | Higher (shaft + seals + bearings) |

The hybrid propeller demonstrates that with the right geometry and design tools, it’s possible to achieve:

- Longer mission endurance

- Energy-efficient, quieter operation

- Safer navigation in challenging environments

The Bigger Picture: Design Innovation with CAESES

The project showcases how CAESES helps engineers model complex geometries, efficiently search large design spaces, and link CAD to simulation tools. This facilitates the design-to-analysis workflow, accelerating innovation in marine propulsion and other design areas. The combination of intelligent design and advanced digital toolsets is crucial for creating effective, reliable, and green propulsion systems.

About the Author

Tomáš Jakuš completed this research as part of his bachelor’s degree in mechanical engineering at Brno University of Technology. The work was supervised by Ing. David Štefan, Ph.D., and highlights modern design approaches at the intersection of fluid dynamics, marine engineering, and parametric modeling.

Read the full thesis:

Design and Optimization of the Geometry of a Peripherally Driven Water Drone Drive

FRIENDSHIP SYSTEMS: Shaping the Future of Marine Propulsion

At FRIENDSHIP SYSTEMS, we help engineers design more and faster with CAESES, our computational platform for simulation-driven design. With CAESES, you have complete control of your geometry and the performance-based parameters that are critical to your design, keeping your design efficient, while innovating.

From early concepts to detailed propeller optimizations, CAESES integrates parametric modelling with simulation and optimization tools to facilitate the entire workflow. This integration leads to rapid development, improved performance, and organized creative potential.

Are you ready to accelerate your next project? Contact us today.