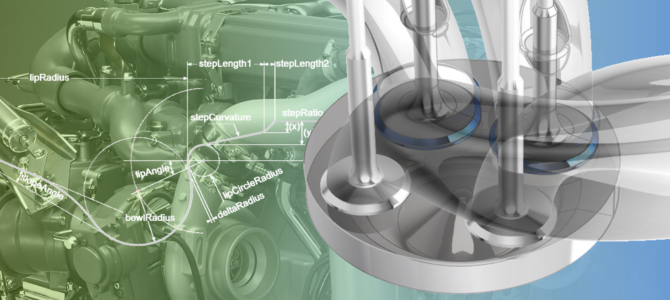

As the internal combustion engine continues to evolve, driven by tighter emission regulations and efficiency targets, engineers face increasing pressure to create cleaner, more efficient designs. A good piston bowl design is crucial for optimizing combustion in diesel and direct-injection gasoline engines. It significantly affects fuel-air mixing, emissions, and overall engine performance.

Specifically, the piston bowl’s geometry directly influences:

- Combustion efficiency

- Soot and NOx emissions

- Fuel consumption

- Power output

Finding the ideal compromise between these requirements is necessary to design a suitable piston bowl, which is no easy feat. Engineers can accomplish this balance more quickly, precisely, and flexibly with the help of CAESES – an intelligent, automated solution.

It can create fully parametric piston bowl models with easily adjustable key design elements. Users can instantly create valid geometry variants ready for simulation by changing parameters like bowl depth, lip profile, and re-entrant shape with a few clicks.

But CAESES is more than just a geometry tool; it makes it possible to automate full design studies and optimizations – including state-of-the art approached based on machine learning. In a smooth workflow, hundreds of piston bowl shapes can be generated, evaluated, and improved – saving time, lowering manual labor, and producing designs that strike the ideal balance between emissions and performance.

Why Piston Bowl Design is so Challenging

Bowl depth, lip height, re-entrant angles, and overall contour shape are just a few of the many variables that determine the piston bowl’s geometry. They have to be finely tuned to obtain a good and well-balanced design that:

- Promotes strong swirl and tumble motion to mix air and fuel effectively.

- Enhances homogeneity of the air-fuel mixture for cleaner combustion.

- Supports fast, complete combustion with minimal ignition delay.

- Ensures centralized combustion away from cylinder walls to reduce heat losses and emissions.

- Reduces NOx by controlling peak combustion temperatures.

- Limits soot formation by promoting better mixing and avoiding fuel-rich zones.

- Avoids direct impingement of fuel spray on the piston bowl walls or cylinder liner.

- Ensures strategic impingement if needed to improve mixing without causing wetting.

- Matches spray angle, nozzle type, and injection pressure.

- Is designed to work with multiple injection events (pilot, main, post).

On top of this complexity, engineers must work within strict design constraints, for example:

- A fixed compression ratio to keep the engine’s map valid and avoid recalibration, as well to ensure safe design without excessive pressure.

- Minimum wall thicknesses, especially in relation to other internal structures like oil cooling galleries, to avoid structural failure or cracking under thermal and mechanical stress.

- A good match with the injection system to avoid unfavorable impingement of the fuel spray.

Choosing the best design becomes a multifaceted optimization problem, which is further complicated by the requirement to use computationally demanding combustion CFD simulations to assess each potential shape.

How CAESES Simplifies Piston Bowl Design

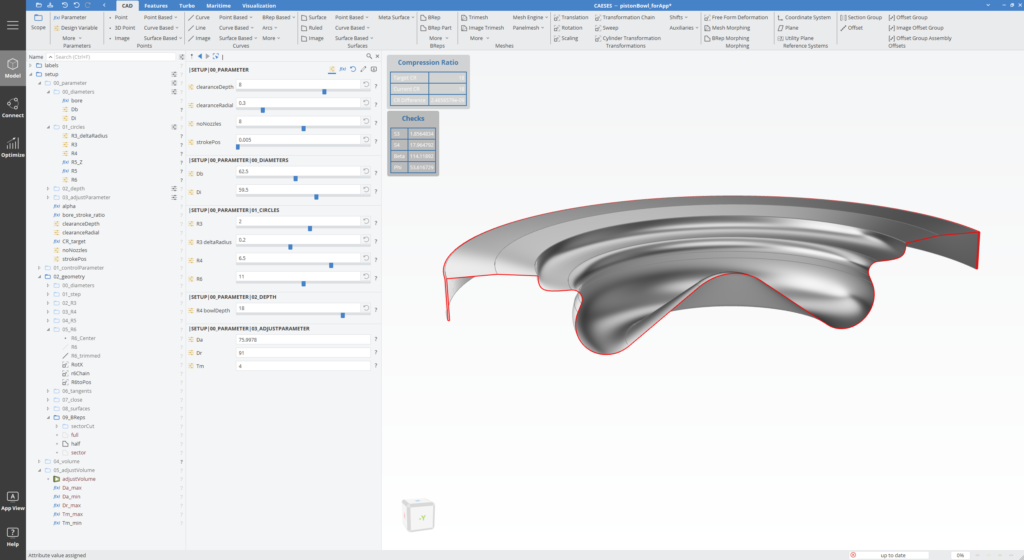

On top of the integrated simulation- and data-driven design capabilities that CAESES provides by default, we have developed a new automated workflow that is now available to users dealing with piston bowl design applications.

In summary – as demonstrated in the video above – this workflow supports the user in navigating the following tasks:

Rapid parametrization of imported piston bowl geometry

Quickly parametrize an existing piston bowl geometry (from CAD or another source) rather than starting from scratch. By this process, the static geometry is transformed into a flexible, completely controllable model with easily adjustable key parameters such as the re-entrant angle, lip profile, and bowl depth.

Automated creation of design variants

Once parameterized, the model can generate a large number of design variants automatically. These variants can be used for:

- Design of Experiments (DOE) studies

- Single- or multi-objective optimizations

- Sensitivity analyses

Importantly, the workflow allows engineers to enforce critical constraints – such as keeping the compression ratio fixed – ensuring that every variant within the design process remains valid.

Seamless integration with CFD solvers

CAESES connects with leading CFD packages (e.g., CONVERGE, AVL FIRE, STAR-CCM+) to fully automate the loop:

- Generate a geometry variant and export a ready-to-use computational domain.

- Run the CFD simulation.

- Evaluate key outputs (soot, NOx, efficiency, etc.).

- Feed results back into the optimization or machine-learning algorithm.

This enables true simulation-driven design exploration, where hundreds of designs can be analyzed systematically, as well as the training of machine learning models for data-driven engineering

Tailored workflows for different piston bowl types

This workflow is not restricted to a single engine type or bowl shape. The parametric model and automated procedure can be tailored to the particular application, regardless of whether the piston bowl is toroidal, re-entrant, or of another design.

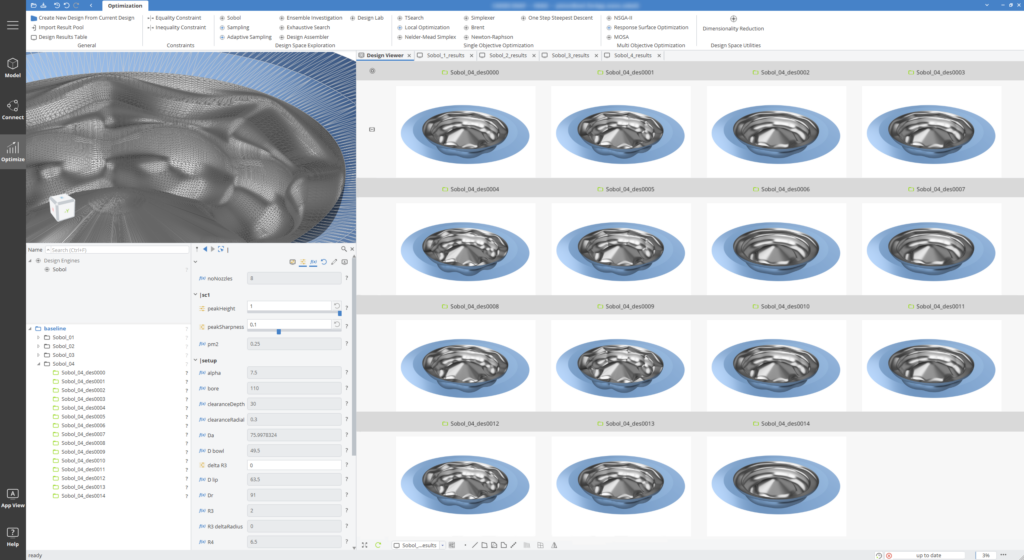

Proven Success: Diesel Piston Bowl Optimization Case Study

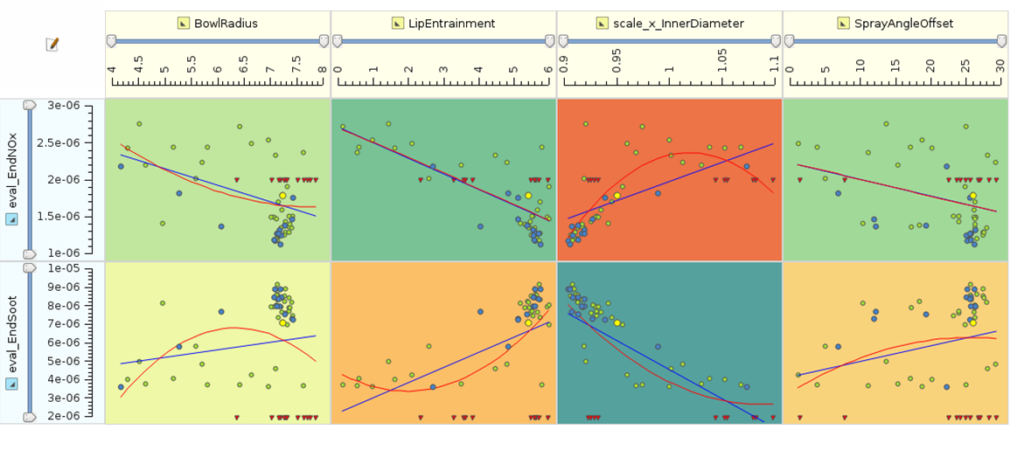

In a real-world project, CAESES was used to optimize the piston bowl of a diesel engine with the goal of improving the concurrent objectives of soot and NOx production, while strictly keeping the compression ratio constant.

Using CAESES, engineers set up an automated process that generated and evaluated around 50 design variants. The result? A piston bowl geometry that met the stringent emission targets without compromising other performance requirements – all achieved in a fraction of the time that a manual process would require.

Beyond Piston Bowls: Custom Workflows for Your Design Challenges

At CAESES, we understand that every engineering problem is unique. That’s why we support our users in creating customized workflows not just for piston bowls, but for a wide range of complex components – from intake ports to turbocharger impellers and beyond.

Our mission is to help you:

- Speed up your design cycles

- Explore better designs through simulation

- Meet tough performance and emission targets

Get Started Today

If you’d like to learn more about how CAESES can help you design cleaner, more efficient engines – or if you want to discuss a customized solution for your application – contact us today.

🔗 Learn more about piston bowl design with CAESES

🔗 See the piston bowl optimization case study