Engineering teams today face increasing pressure to deliver high-performance designs faster and with fewer resources. While advanced simulation tools like CFD and FEM are widely used, many teams still struggle with fundamental challenges in parametric modelling, optimization, and design automation.

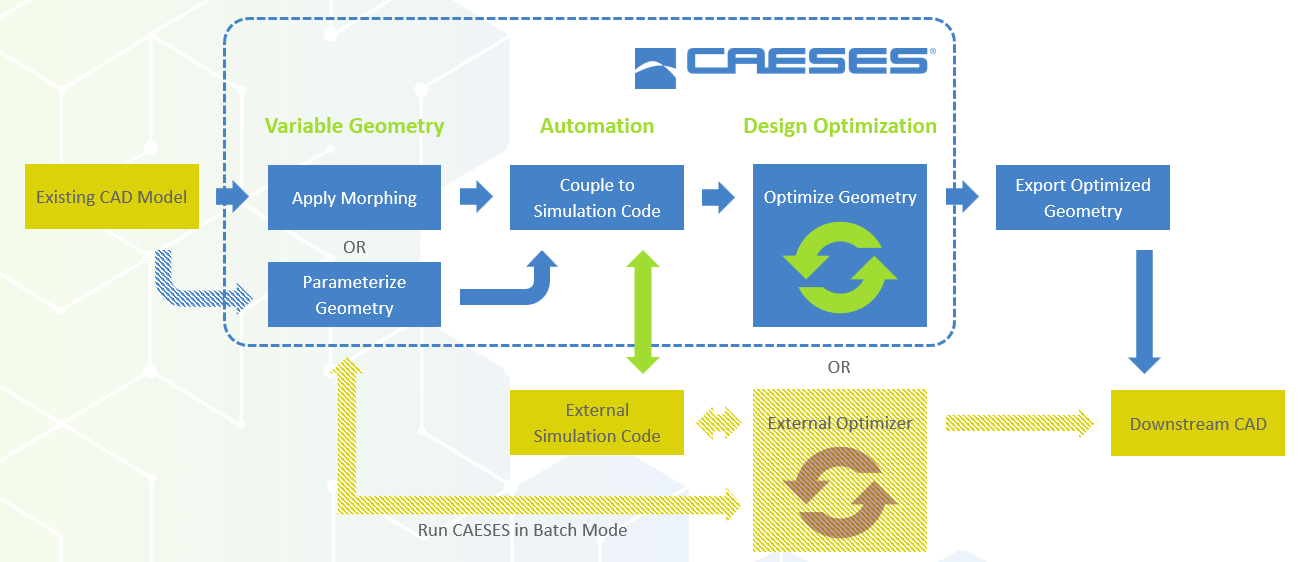

In this blog, we highlight five common engineering challenges that slow down simulation-driven design and explain how CAESES, our parametric geometry exploration and optimization platform, helps teams overcome them.

1. Creating Robust Parametric Geometry Models

One of the biggest challenges in simulation-driven engineering is building robust parametric geometry models. Most CAD tools are focused on detailed design and manufacturing intent. Their models only function within narrow “safe” parameter ranges. As soon as parameters move outside these ranges, the geometry fails to regenerate or produces unreasonable shapes.

Typical causes include:

- Fragile feature-based CAD histories

- Unstable topology changes

- Models not designed for automation or optimization

Why this matters to engineering teams:

Broken geometry interrupts automated workflows, delays simulations, and forces engineers into time-consuming manual fixes.

How CAESES helps:

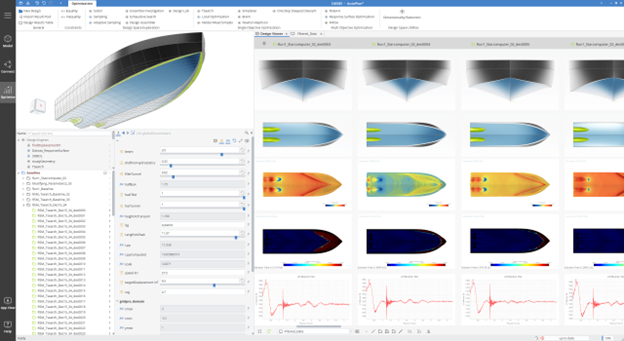

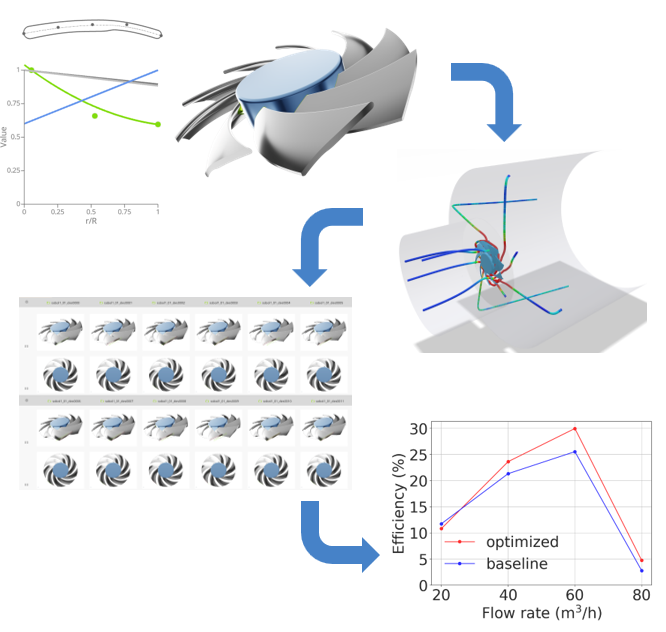

CAESES is designed specifically for robust parametric modelling for shape variation. Its dependency-based surface modelling approach ensures geometry remains stable across wide parameter ranges, making it ideal for design space exploration, CFD automation, and optimization studies.

2. Identifying Dominant Design Parameters

Modern engineering models often include dozens of parameters, but not all of them influence performance in meaningful ways. Teams frequently struggle to identify which design variables actually matter.

Common issues include:

- Too many parameters with unclear impact and redundancies

- Limited visibility into sensitivities

- Time wasted optimizing low-impact variables

Why this matters:

Without understanding dominant design drivers, optimization efforts become inefficient and unfocused.

How CAESES helps:

CAESES supports design sensitivity analysis and structured design exploration, helping engineers quickly identify the parameters that drive performance. This allows teams to reduce complexity, focus optimization efforts, and make data-driven design decisions.

3. High-Dimensional Design Spaces with Competing Objectives

Real-world engineering problems rarely involve a single objective. Teams must typically cover vast design spaces and balance performance for different measures of interest and/or operating points, often within limited development timelines.

As design complexity increases:

- Manual iteration becomes impractical

- Trade-offs are difficult to quantify

- Good designs are hard to uncover, and teams settle for “good enough” designs

Why this matters:

Without systematic optimization, teams risk missing better design solutions.

How CAESES helps:

CAESES enables automated multi-objective optimization, allowing engineers to explore high-dimensional design spaces efficiently. By visualizing trade-offs and Pareto fronts, teams can confidently select optimal design compromises based on data and not intuition.

4. Tightly Constrained Optimization Problems

Many engineering projects are governed by strict constraints such as:

- Packaging and installation limits

- Manufacturing rules

- Regulatory or performance thresholds

In such cases, most randomly generated designs are infeasible, causing optimization workflows to fail or slow down.

Why this matters:

Optimization algorithms waste time evaluating invalid designs, and engineers spend effort fixing geometry instead of improving performance.

How CAESES helps:

CAESES integrates constraints directly into the parametric geometry definition, ensuring that only feasible designs are generated. This dramatically improves optimization efficiency especially for tightly constrained engineering problems.

5. Schedule Overruns Due to Manual Redesign Loops

Late design changes are inevitable but manual redesign loops shouldn’t be. Many schedule overruns occur because:

- Requirements aren’t fully integrated early

- Geometry models lack flexibility

- Changes cascade across CAD, meshing, and simulation

Why this matters:

Each redesign loop increases cost, risk, and time-to-market.

How CAESES helps:

CAESES enables requirement-driven parametric design, allowing geometry to adapt automatically as inputs change. This reduces manual rework, keeps simulation workflows consistent, and helps engineering teams stay on schedule.

Conclusion: Enabling Smarter Engineering

The challenges engineering teams face today are not caused by a lack of tools but by inefficient geometry and workflow management.

By combining robust parametric modeling, design automation, and optimization-ready geometry, CAESES helps teams:

- Build stable parametric models

- Identify key performance drivers

- Explore complex design trade-offs

- Solve tightly constrained optimization problems

- Reduce costly redesign cycles

CAESES empowers engineering teams to move from trial-and-error to data-driven, simulation-first design without sacrificing speed or reliability.